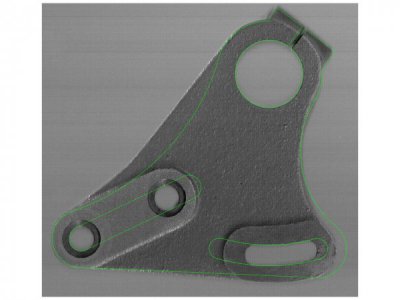

After many many projects I have finally got around to testing all of the gears sets that I and MontanaAardvark (shortened to MA throughout this post for simplicity) claim interfere with the input shaft gear spacer ring (its the part circled in red on the photo in MA's first post and also in below photo) and the electronics box that is inside of the change gear cover. I also used the Supplement to the Sieg SC4 Instruction Manual written by Robert Ackert as a source as it omits any gear sets from its imperial threading chart that he felt would not physically fit on the machine due to interference.

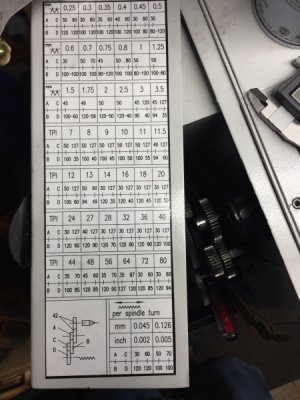

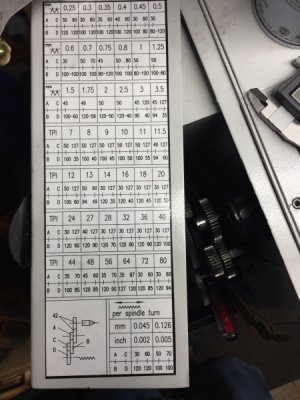

For a quick recap, Sieg states that the following threads can be cut on the SC4 lathe. See pic below

I tested all metric pitch change gears first and they all fit on the banjo inside of the change gear cover without any issues or interferences with the input shaft or the electronics box. I then tested the imperial change gears and found that 7 - 24, 48, 56, 72, and 80 TPI also fit on the banjo with it inside of the change gear cover without any issues or interferences. I skipped 27 TPI because, well its 27 TPI, who will ever need to thread 27 TPI !! The following imperial change gears

did not fit in the same manner that the other gears did. This includes 28, 32, 36, 40 and 64 TPI. Right now in this post I will address 28 TPI only as it can work with slight modifications and without the need to rotate the banjo 180° outside the cover or make a new banjo. All of the other non fitting TPI's I will address in my second post which will come shortly after this post.

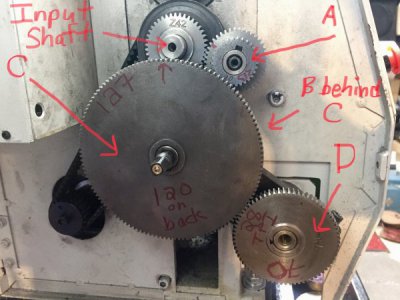

Ok, when I got to 28TPI I encountered a problem as well as did MA. First take a look at the below picture as it will be easier to describe the issue using a visual reference. Take notice to the arrow on the 127 tooth gear which points at the input shaft. This is where the interference takes place.

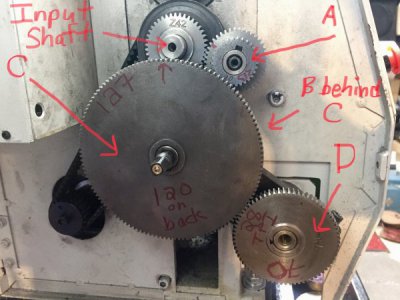

The below picture shows the components that I removed off of the input shaft to allow clearance to the 120 tooth B gear which is behind the 127 tooth C gear. The spacer ring slides over the input shaft and a washer and SHCS (not pictured) retain it to the shaft. These components can be removed if a modification is made to the input shaft or they can be modified which I will explain below.

For 28 TPI the following set of 4 gears must be used. A/B=30/120 and, C/D=127/70.

The 120 tooth Gear B is way to close to the input shaft. I have the retaining ring, (washer and SHCS not shown) but with all of that out of the way the key is still an issue.

I am going to list 2 of the more simpler ways of modifying components to get around the 28 TPI issue and I will explain them in detail. I will post my other 2 optional ways to make this gear combo work inside the door in a later post but they require a modified banjo similar to the EMCO banjo.

Option 1

The first and easiest option which requires the least amount of work is to first make a new spacer ring for the input shaft. The key slot will be omitted. The ID of the ring will remain at 16MM (.63") but the original 21.8MM OD (.858") will now be 17.26MM OD (.68"). You will also want to eliminate the washer and make it part of the spacer. You don't have to do this but I figure it's much easier than trying to find a washer with a .68" OD or turning one down to size. Also if the hole in the washer is not tight on the threads it may have runout and make it hard to make it concentric with the spacer and in return cause an interference. Remember, there is only just shy of 2MM (.078") between the gear and the shaft.

The OD of the ring could possibly be another .25MM to .5MM (.010" to 020") bigger because when I checked for clearance I made sure the gear mesh was as tight as possible but in reality you wouldn't want zero backlash between the gears and also the tolerance from one machine to the other will vary.

Lastly you will need to mill down the section of the input shaft key that protrudes from the gear on the outboard side. It should be milled down so that it is flush with the top of the shaft. This will allow the thin spacer to slide over the shaft.

And before anyone says it, I know, I know, a spacer that has a wall thickness of .63MM (.060") is pretty thin but remember, the only purpose of this spacer is to keep the gear from walking on the shaft. It will not see a load from the gear train so the 4MM SHCS does not need much torque, just snug. Secondly, this is only for use when threading 28TPI.

This method is completely reversible and will not prevent you from going back to the factory parts whatsoever although you will need to source an additional key.

Option 2

The second option is to remove the input shaft and turn a groove on the shaft at the outboard location of the gear and install a C-clip (also called a circlip) to retain the 42 tooth gear from walking. This method is already used on the inboard side of the gear to retain it from walking. You will also need to shorten the key so that it is no longer than the gear. This method eliminates the spacer washer and SHCS and gives you the most clearance between the B gear and the input shaft. This method is also completely reversible and will not prevent you from going back to the factory parts whatsoever.

Below picture shows the combined options 1 and 2.

Please let me know what everyone's thoughts are and if you have an idea that will work better please chime in and let me know your thoughts.