- Joined

- Feb 2, 2013

- Messages

- 3,628

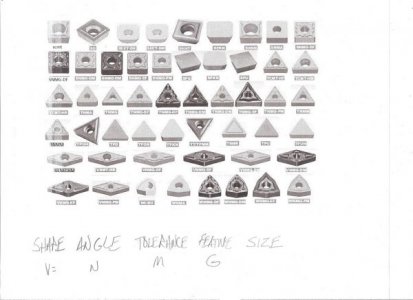

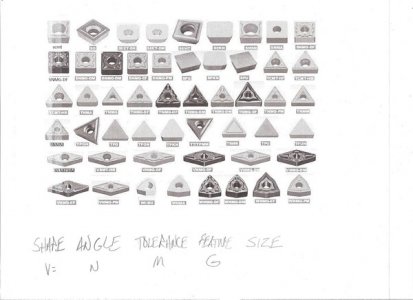

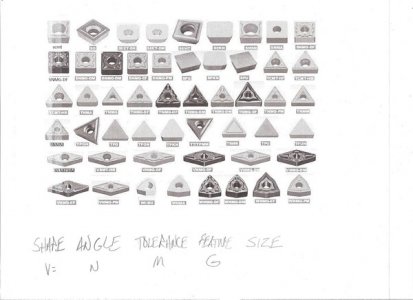

i scanned a carbide insert chart that i keep in my shop reference binder.

maybe it may help others out in identifying stray inserts.

https://lh6.googleusercontent.com/-OgVM8no9E5g/V-qDBoHAW4I/AAAAAAAAISU/CHW6jb9GVHgAtKZbxtNBXFfjYHiQlMh5gCL0B/w1141-h830-no/Insert+chart.jpg

maybe it may help others out in identifying stray inserts.

https://lh6.googleusercontent.com/-OgVM8no9E5g/V-qDBoHAW4I/AAAAAAAAISU/CHW6jb9GVHgAtKZbxtNBXFfjYHiQlMh5gCL0B/w1141-h830-no/Insert+chart.jpg

Last edited: