It does not take much to move the chuck with the side screws even when pretty darned tight. You can see this with the a dial indicator when you move one of the screws. I don't have the front screws tightened down with an impact wrench. I think I have them at 40-60 ft. lbs. I'd completely forget the the number.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

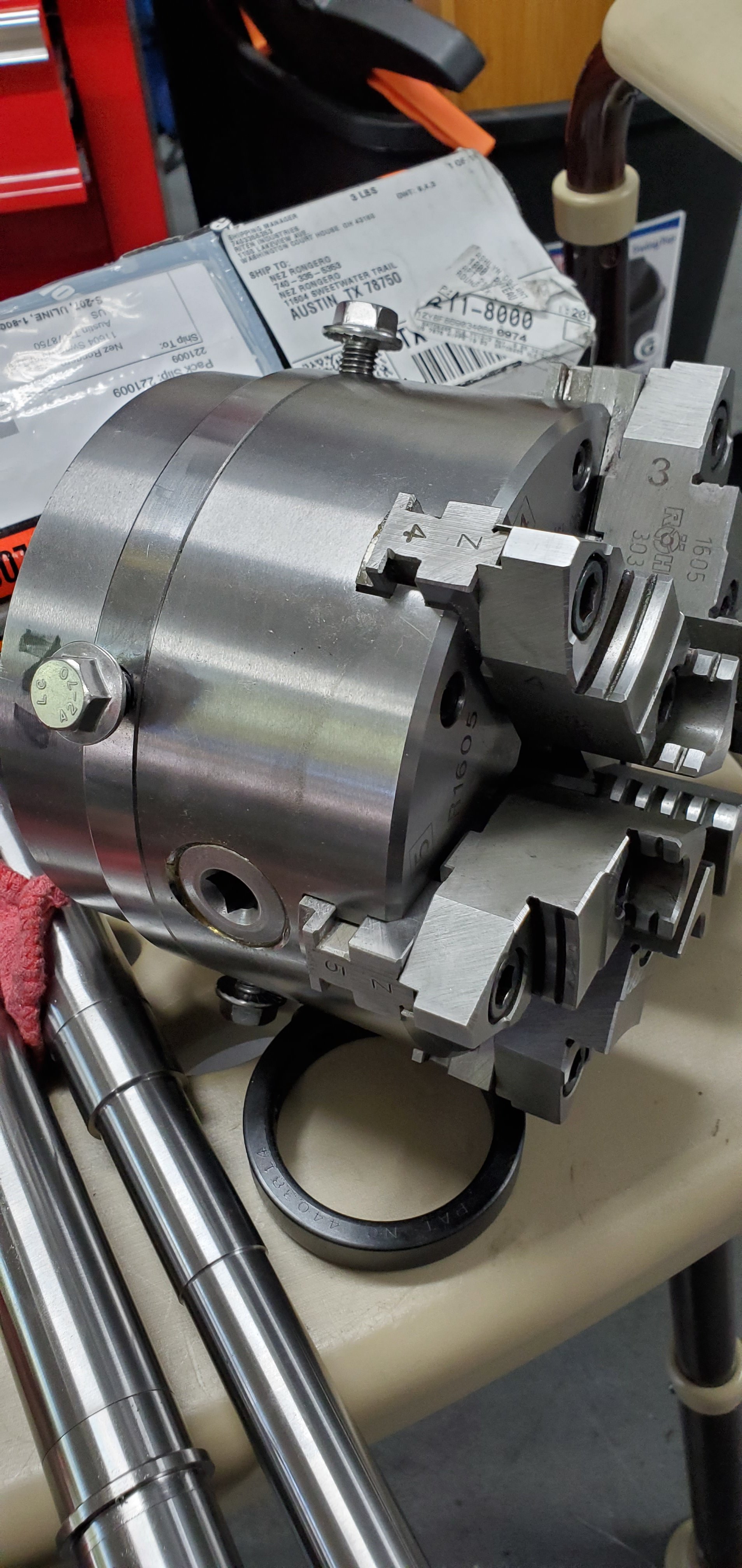

Chandox 3DAKT-06 3 jaw "adjust true" chuck

- Thread starter Dpaul7

- Start date

- Joined

- Feb 11, 2020

- Messages

- 29

Regarding my new Chandox chuck.

I was successful in breaking the hex screws loose with an impact wrench. However, the four adjusting hex screws around the perimeter will not budge whatsoever. I have loosened each one and applied a good deal of force with a solid hex wrench to each one independently in turn. No movement on the dial indicator in any direction. The chuck is still out about 0.0055". Any suggestions? I don't want to break anything.

I was successful in breaking the hex screws loose with an impact wrench. However, the four adjusting hex screws around the perimeter will not budge whatsoever. I have loosened each one and applied a good deal of force with a solid hex wrench to each one independently in turn. No movement on the dial indicator in any direction. The chuck is still out about 0.0055". Any suggestions? I don't want to break anything.

I took the chuck apart and removed .005-.010" from the backplate. That gave me a lot more movement in adjusting the chuck. If I remember correctly, mine didn't move at all, just like yours.

You don't need to tighten those side adjusting bolts too much. I did that and recently took the chuck apart only to find the backing plate had cracked sections where the side bolts are.

You don't need to tighten those side adjusting bolts too much. I did that and recently took the chuck apart only to find the backing plate had cracked sections where the side bolts are.

- Joined

- Jul 13, 2014

- Messages

- 1,051

I would take the chuck apart and do a clean up. Measure the clearance for the chuck to move, follow Shars recommended clearances.

zero-set-manual-pages

When you try to dial a test bar, I would keep the 4 screws loose and just tap the front section of the chuck to get minimal runout, then adjust the 4 screws for final minimal runout

zero-set-manual-pages

When you try to dial a test bar, I would keep the 4 screws loose and just tap the front section of the chuck to get minimal runout, then adjust the 4 screws for final minimal runout

- Joined

- Jul 13, 2014

- Messages

- 1,051

How do you take it apart? Do you remove the bolts on the back first?

Loosen the adjusters, remove the clamp bolts, the chuck pulls out from the backplate

- Joined

- Jul 13, 2014

- Messages

- 1,051

Unsolicited input.

When I got these 6Js, the first I did was replaced the set screw adjusters with flange bolts. Life is a lot easier compared to messing with Allen wrenches.

Safety police might have a cow with the flange bolt heads sticking out. The sharp corners of the jaws stick out further when I chuck up even a 1 inch OD turned barrel. Secondly, never reach in to any rotating mass.

When I got these 6Js, the first I did was replaced the set screw adjusters with flange bolts. Life is a lot easier compared to messing with Allen wrenches.

Safety police might have a cow with the flange bolt heads sticking out. The sharp corners of the jaws stick out further when I chuck up even a 1 inch OD turned barrel. Secondly, never reach in to any rotating mass.

- Joined

- Dec 20, 2012

- Messages

- 9,422

You want the full range of movement the adjusters will allow. Remove the chuck from the back plate as Bamban said, then measure the travel on each of the adjusters. Basically, just retract the pin fully and then extend it fully and measure that travel. That gives you the range of each pin. Then turn the snout of the backplate down to allow for that much clearance.

For example, say each adjuster allows for 0.040" of range. The snout OD should at least 0.020" smaller than the ID of the cavity in which the snout resides. That allows the snout that full range of travel. Ideally, the bolts that hold the chuck to the back plate will also allow that much travel.

If you have a tap and die for the adjusters, clean the threads for the screws.

For example, say each adjuster allows for 0.040" of range. The snout OD should at least 0.020" smaller than the ID of the cavity in which the snout resides. That allows the snout that full range of travel. Ideally, the bolts that hold the chuck to the back plate will also allow that much travel.

If you have a tap and die for the adjusters, clean the threads for the screws.