For those suggesting brands / venders Paul is in Latvia so US suppliers are probably not much help.

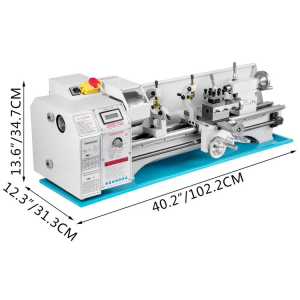

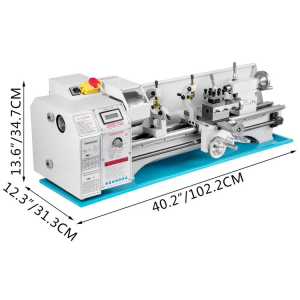

It comes with simple tailstock, I would like to buy with bearings and tool holder/toolpost, do not know how it is called, but as far as I understand it gives ability to change tools easily. What else should I look for?

Thank you

The bearings you refer to are live centers, the solid type are dead centers.

The tool post is a quick change tool post, the one pictured is an Aloris type, which is the most common style. You will probably want an OXA size, but a lot of people with 9x20" lathes prefer the AXA size. The MX750 has an 8.7" swing which is nearly the same as the 9x20s 8.75" but can't say for sure that will work for the MX750, so OXA is probably the safer choice.

This type of tool post can be had as the wedge type or piston type, the wedge is preferred, but both work. The one in your photo is the wedge type, named for the moving wedge that locks the tool post. The piston type is simpler so sometimes cheaper and has a round piston that extends from the body to lock the tool holder.

I would look for a tool post made of steel, some are made from aluminum and not as solid, but again often cheaper.

You will probably want to get additional tool holders, most just come with a few holders to get you started.

If you are going to be working on pipes, you may want to get a bull nose center. These have a broader point to fit into the end of a pipe or tube. They come in different sizes to fit different size tubing. The point on a standard center will not hold a very large piece of pipe or tubing because they are usually only 1/2"-1" / 12-25mm in diameter. Bull nose centers come in much larger sizes 2" / 50mm, and 4" 100mm being common.