Probably should take it off, clean, lubricate, put backNot sure which brands on AliExpress are good but I've used the cheap ones and they will chip if not treated carefully.

MT2 and MT3 are two different sizes, here's a reference doc. https://solutions.travers.com/metalworking-machining/how-to-determine-your-machines-taper-size Edit: Sorry, the difference between A and B in the picture you posted is the tang on the back which is used for driving the taper out of (usually) a spindle. It may not be needed for a tailstock which has a screw which should eject the taper when you retract the ram all the way back into the tailstock. You can always cut off the tang if not needed should you purchase type A.

Yes, tighten up that piece on the back of the carriage as tight as it'll go and still let it move freely, make sure you have plenty of way oil in there too.

John

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese lathe upgrades.

- Thread starter PaulsM

- Start date

Check you tube: iirc youtuber Adventures in a very small lathe covers this verywell.Also, I have a wobble in this part, I see it can be tightened, but how much is enough?

View attachment 434484

View attachment 434481

I think Aliexpress is a crap shoot.Any suggestions what is a good "brand" on aliexpress for cutting bits?

Also, could someone explain MTA and MTB?

View attachment 434437

Go with something in your price range and low shipping cost. Who knows what will show up.

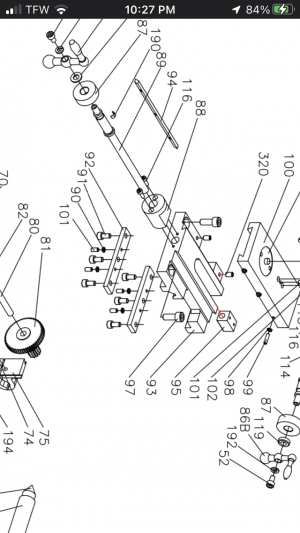

You need to adjust these, found on search for MX750 lathe manualAlso, I have a wobble in this part, I see it can be tightened, but how much is enough?

View attachment 434484

View attachment 434481

Although I did not see any mention of actual adjustment in the manual. # 90,91.92 and 101.

- Joined

- Aug 22, 2012

- Messages

- 4,116

those plates/gibbs numbered 92 above might be push pull screws, screw up tight till the saddle barely moves then screw in the push screws a tad at a time till the movement is smooth and firm, its a bit of an iterative process.

Both the front and rear plates are probably adjusted in the same manner.

You may find on your lathe those plates are not flat but an "L" section where the foot of the "L" bears upon the bottom of the bed, still the same process.

Both the front and rear plates are probably adjusted in the same manner.

You may find on your lathe those plates are not flat but an "L" section where the foot of the "L" bears upon the bottom of the bed, still the same process.

Where did you get so nice picture? All I have is a bad copy of manual where pictures are blurred, thats what they gave meYou need to adjust these, found on search for MX750 lathe manual

Although I did not see any mention of actual adjustment in the manual. # 90,91.92 and 101.

View attachment 434558

I just search MX 750 lathe manualWhere did you get so nice picture? All I have is a bad copy of manual where pictures are blurred, thats what they gave me

Got my hands on my chinese lathe today.. saddle (I guess its called like that) had a huge play, so I watched some youtube videos and got it tight. There was no "feelable" movement anymore, if I tighten those first plates more, it would bind on rails. So I tried my first turning and.. its horrible

Toolmarks all over the place and after all I can move whole toolpost, so its not rigid (cant see or feel, but while cutter is on pipe I can move it and see new toolpath +soud. More tweaking or its just chinese style?

Toolmarks all over the place and after all I can move whole toolpost, so its not rigid (cant see or feel, but while cutter is on pipe I can move it and see new toolpath +soud. More tweaking or its just chinese style?

More tweekingGot my hands on my chinese lathe today.. saddle (I guess its called like that) had a huge play, so I watched some youtube videos and got it tight. There was no "feelable" movement anymore, if I tighten those first plates more, it would bind on rails. So I tried my first turning and.. its horrible

Toolmarks all over the place and after all I can move whole toolpost, so its not rigid (cant see or feel, but while cutter is on pipe I can move it and see new toolpath +soud. More tweaking or its just chinese style?

Check every nut,bolt,screw you can find and make sure they are not loose.

Then readjust all your gibs. It takes time and im not sure what type of metal pipe you have but some metals just finish awful and also if you cant get to the speeds and feeds needed for carbide to shine switch to HSS cutters

Im only slightly ahead of you, lol

Last edited: