- Joined

- May 27, 2016

- Messages

- 3,471

This is about attempting to machine a new quill, in a case of using one lathe to fix up another. I searched the net, and found that quills can be made of alloy steel, or high strength cast iron. My thoughts were that it needs high strength and be able to take impact, easy machining, not ultra-hard, corrosion resistant would be nice. The older South Bend 9C is in good condition, but the South Bend 9A tailstock quill has been greviously mangled. The MT2 taper was partly drilled out off center. Amazingly, what remains of the MT2 still grabs onto a taper, but is not properly supported. It needs a new quill!

Parted-out South Bend tailstocks turn up on eBay, but the risk is repeatedly shelling out for a banged-up old part of unknown internal condition, so I was thinking to use the SB9C to make a new quill for the SB9A. (There is a kind of poetic justice in that)! We get to choosing the steel.

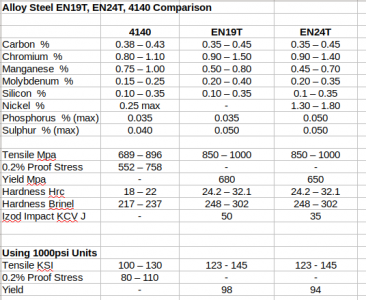

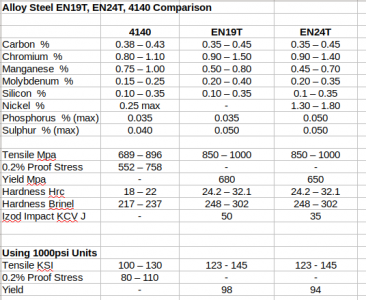

I thought 4140. More easily available in UK is EN19T and EN24T. I found some specifications and set them together as a compare list. The info I have on 4140 mentions "0.2% Proof Stress" which may be yield-related, but the other two steels show "yield" instead. I tried to convert units, but not guaranteed to be error-free. Mpa is the same as N/mm2. KSI is "kilo-pounds per square inch".

The steels all seem very similar, and I guess a quill could be made out of any of them. 4140 seems more tightly controlled when it comes to impurities. EN19T is readily available, slightly lower cost than the other two. EN24T looks kind of similar to 4140, except it has a bigger dollop of nickel, and is a bit stronger.

Enough EN24T to make two quills is £16.50 (about $20).

So where am I going with this? First is to just ask which would be your preference. Would you use something else? Does anyone know what the South Bend quills were made of in the first place?

The next thing, given my relative inexperience, is to seek advice on actually making it. The quill measures 5.125" long x 1.070" diameter, so I guess around 28mm, or 1.125" is the starting out raw size. A precision centered taper and a 1/2" x 10 ACME thread on a alloy steel quill is not a trivial thing, and it may take me a couple of tries before I get it right. I could use an ACME tap, but I was thinking to just use a ready-made bronze ACME nut insert turned to fit and secure into the back of the quill, just like was done for the SB9C.

I don't have a mill, so I have no idea what to do to cut the anti-rotation slot. I may have to find some milling help from a pal. I did see some dude on YouTube use an angle grinder with a cutting disk to hack out most of a quill slot, and then finish with a file (shudder)! Maybe I can clamp a tool sideways, and move the saddle to carve the slot out. Hmm - is that a crazy notion?

Parted-out South Bend tailstocks turn up on eBay, but the risk is repeatedly shelling out for a banged-up old part of unknown internal condition, so I was thinking to use the SB9C to make a new quill for the SB9A. (There is a kind of poetic justice in that)! We get to choosing the steel.

I thought 4140. More easily available in UK is EN19T and EN24T. I found some specifications and set them together as a compare list. The info I have on 4140 mentions "0.2% Proof Stress" which may be yield-related, but the other two steels show "yield" instead. I tried to convert units, but not guaranteed to be error-free. Mpa is the same as N/mm2. KSI is "kilo-pounds per square inch".

The steels all seem very similar, and I guess a quill could be made out of any of them. 4140 seems more tightly controlled when it comes to impurities. EN19T is readily available, slightly lower cost than the other two. EN24T looks kind of similar to 4140, except it has a bigger dollop of nickel, and is a bit stronger.

Enough EN24T to make two quills is £16.50 (about $20).

So where am I going with this? First is to just ask which would be your preference. Would you use something else? Does anyone know what the South Bend quills were made of in the first place?

The next thing, given my relative inexperience, is to seek advice on actually making it. The quill measures 5.125" long x 1.070" diameter, so I guess around 28mm, or 1.125" is the starting out raw size. A precision centered taper and a 1/2" x 10 ACME thread on a alloy steel quill is not a trivial thing, and it may take me a couple of tries before I get it right. I could use an ACME tap, but I was thinking to just use a ready-made bronze ACME nut insert turned to fit and secure into the back of the quill, just like was done for the SB9C.

I don't have a mill, so I have no idea what to do to cut the anti-rotation slot. I may have to find some milling help from a pal. I did see some dude on YouTube use an angle grinder with a cutting disk to hack out most of a quill slot, and then finish with a file (shudder)! Maybe I can clamp a tool sideways, and move the saddle to carve the slot out. Hmm - is that a crazy notion?