-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chuck question

- Thread starter jwmay

- Start date

- Joined

- Dec 3, 2017

- Messages

- 1,909

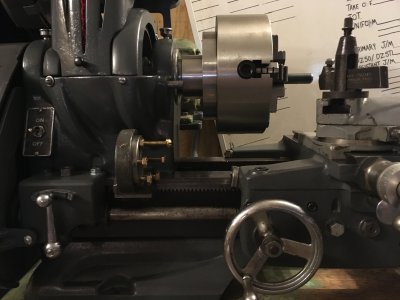

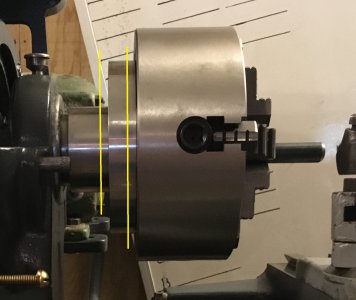

I was measuring from where the backplate begins. I may be confused when you say flange. I would say this backplate looks like a flange. A smaller OD barrel that’s internally threaded, leading to a larger OD section is bolted to the chuck.

- Joined

- Apr 5, 2018

- Messages

- 105

- Joined

- Apr 5, 2018

- Messages

- 105

- Joined

- Dec 3, 2017

- Messages

- 1,909

Thanks for all the replies. I won’t be buying a 500 dollar chuck for it, but at least I know the option is out there.

I may try to thin the backplate. I think I understand what you’re saying RobertB. I’m of the opinion that it sticks too far away from the headstock, but if you all say it’s ok, Then that’s good enough for me. I’ll run it as it is. I don’t have confidence that separating and machining the backplate would turn out well to be honest. There are certain jobs I’ve just really failed at so often that I am reluctant to risk it. Making anything to a precision standard is still fairly elusive for me. And one too long chuck seems better than one brand new wobbly piece of metal attached to the spindle.

I may try to thin the backplate. I think I understand what you’re saying RobertB. I’m of the opinion that it sticks too far away from the headstock, but if you all say it’s ok, Then that’s good enough for me. I’ll run it as it is. I don’t have confidence that separating and machining the backplate would turn out well to be honest. There are certain jobs I’ve just really failed at so often that I am reluctant to risk it. Making anything to a precision standard is still fairly elusive for me. And one too long chuck seems better than one brand new wobbly piece of metal attached to the spindle.

- Joined

- Apr 5, 2018

- Messages

- 105

Your backing plate was pre-mounted, you didn't have to cut the register to fit your chuck?

- Joined

- Oct 18, 2016

- Messages

- 2,872

These guys have a 6" Bison for a bit over $500.00.