- Joined

- Jun 6, 2014

- Messages

- 183

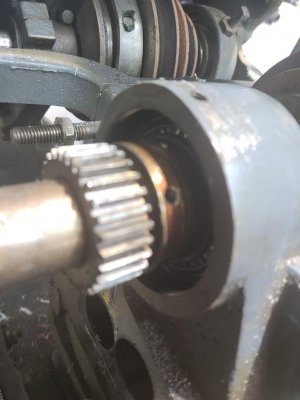

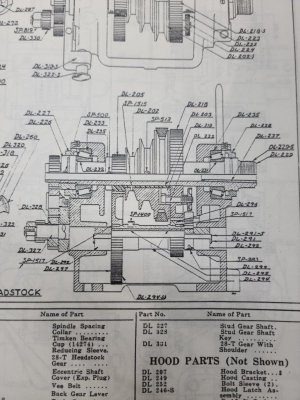

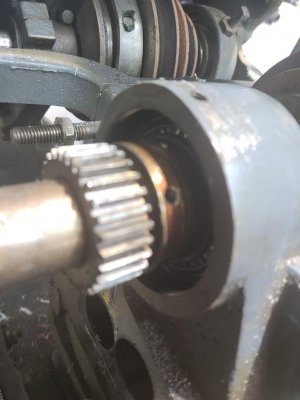

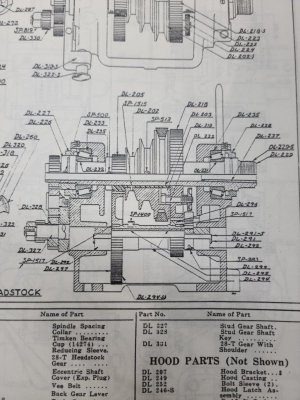

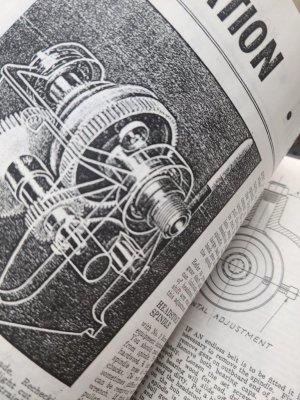

Hi all, I picked up a lovely clausing 111 (small world, I had the same model as my first lathe) over the summer and only recently started getting to use it. I noticed that almost as soon as I added oil to the spindle bearings (both sides) the oil would run out and the bearings would begin heating up. On examination, the oil was coming out between the spindle itself and the screw in nut/cover so I removed them to look for a botched seal. As shown in the pictures, there is a groove where it seems like a packing or o-ring would go on the spindle, but nothing was there. These grooves are also shown in the manual but are never called out and nothing is shown in them or listed on the bom. Does anyone know what should be there that isn't?