- Joined

- May 13, 2019

- Messages

- 1,016

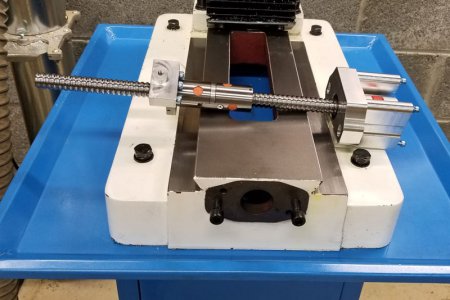

So, I have all my electronics/motors running on the bench. I'm using LinuxCNC with a parallel port breakout board. Many parts were recommended by shooter123456 (Thanks!). My final step is to convert the mechanical parts with ballscrews and motor mounts. I decided to go big and ordered a kit from Dave at arizonavideo. It took some time since I ordered it, but it arrived yesterday. I waited until today to open because of the coronavirus. It looks awesome. Much better than I could ever do.

Now, I need to install this. It looks a little intimidating! There are lots of hardware (screws). Hopefully, it will be obvious as to where they go. There's a little bag with 2 screws in it labelled "TUUI X". No idea what that means.

I notice the couplers don't have setscrews to prevent the motor shafts from spinning. Normal?

The ballscrews have a fitting for lubrication. It looks like a grease fitting. What do I use in here? Way oil? Light oil? Grease?

I'm thinking of doing the X-axis and Y-axis first. Test it briefly and then install the Z-axis. Make sense? The Z-axis looks trickier since I need to remove the gears at the top of the column.

Now, I need to install this. It looks a little intimidating! There are lots of hardware (screws). Hopefully, it will be obvious as to where they go. There's a little bag with 2 screws in it labelled "TUUI X". No idea what that means.

I notice the couplers don't have setscrews to prevent the motor shafts from spinning. Normal?

The ballscrews have a fitting for lubrication. It looks like a grease fitting. What do I use in here? Way oil? Light oil? Grease?

I'm thinking of doing the X-axis and Y-axis first. Test it briefly and then install the Z-axis. Make sense? The Z-axis looks trickier since I need to remove the gears at the top of the column.