- Joined

- Feb 2, 2013

- Messages

- 3,629

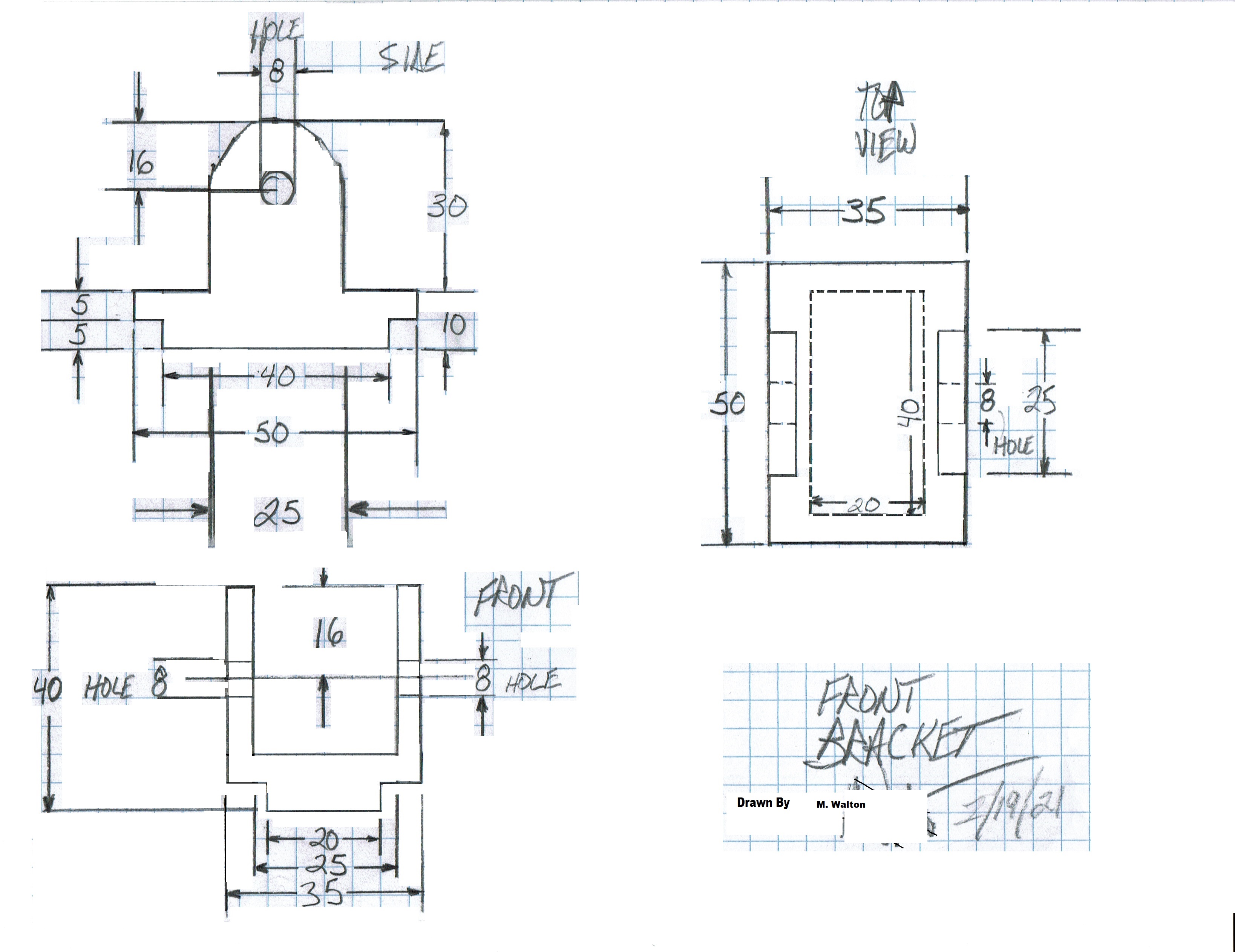

here are pictures of the 3D printed brackets

drawing

drawing

Last edited:

thank you,I'm not a candidate to do the cnc work but would suggest that you provide more details on your innovation up front.

"Those who do not know what cannot be accomplished, are free to accomplish anything."

Thanks brino, your information is valued!Mike,

I do not have the equipment to help you, or much knowledge in CNC but I do have a few thoughts.......

I believe the g-code is machine specific.

That is, the g-code produced for your 3D-printer, may not work on my 3D-printer.

A true 3D solid model (from Solid Works, Fusion-360, Cubify, OnShape, FreeCad and many others) can be turned into g-code but that happens with the specifics of the target machine in mind. The machine specs and the model are inputs, the g-code is the output.

Have you thought about using your 3D-printed part as pattern for green-sand casting in aluminum?

Alternately there's a lost-PLA type casting as well.

-brino

you are 100% correct, i could make these parts manually !Those brackets do not look like anything that needs to be done by CNC. At least from the views you showed us.

All of that would not be bad to do on a manual mill.

I really believe in your sig, Never tell a Polack it cant be done, cuz I never went to no fancy schools to learn it cant be done.

Thank you for the information!There is no way to convert the 3D printer g-code to CNC g-code, they are completely different.

Since you say there is room to modify the design for manufacturability there are a few things to make it easier.

thank you for the great information!!!If you have the STL files, most 3D cad programs can import the STL to get you started on making a real model. It is best to have the parts drawn natively in whichever CAD software you chose. Once you have that done then the parts can be run thru a CAM program or just dimensioned drawings made which any machinist can use to make the parts.