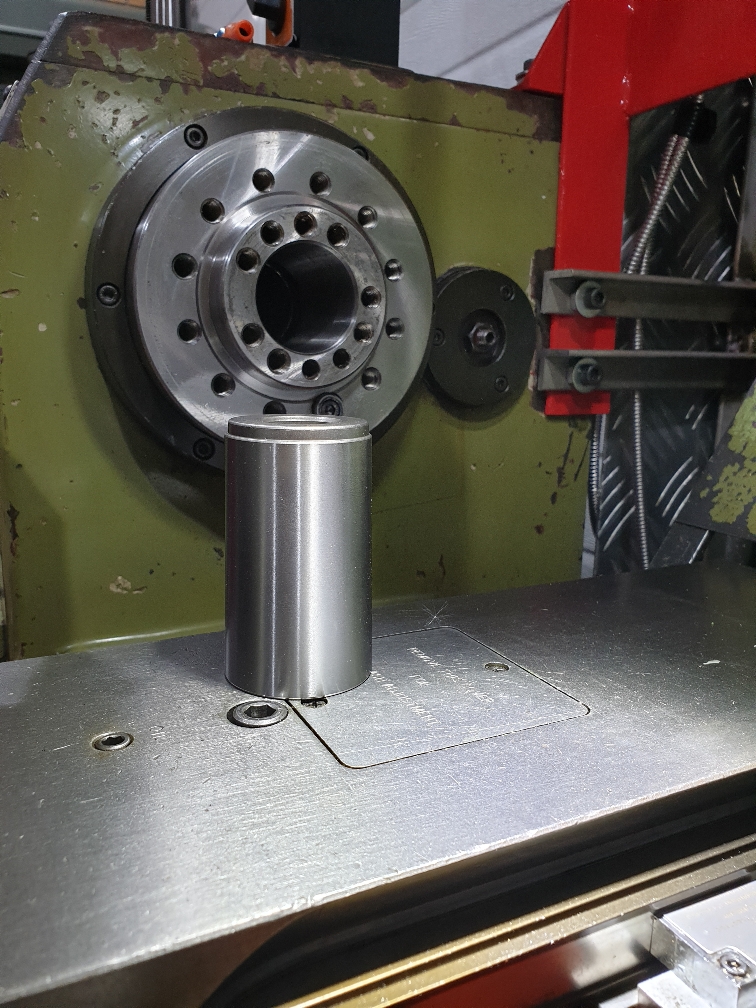

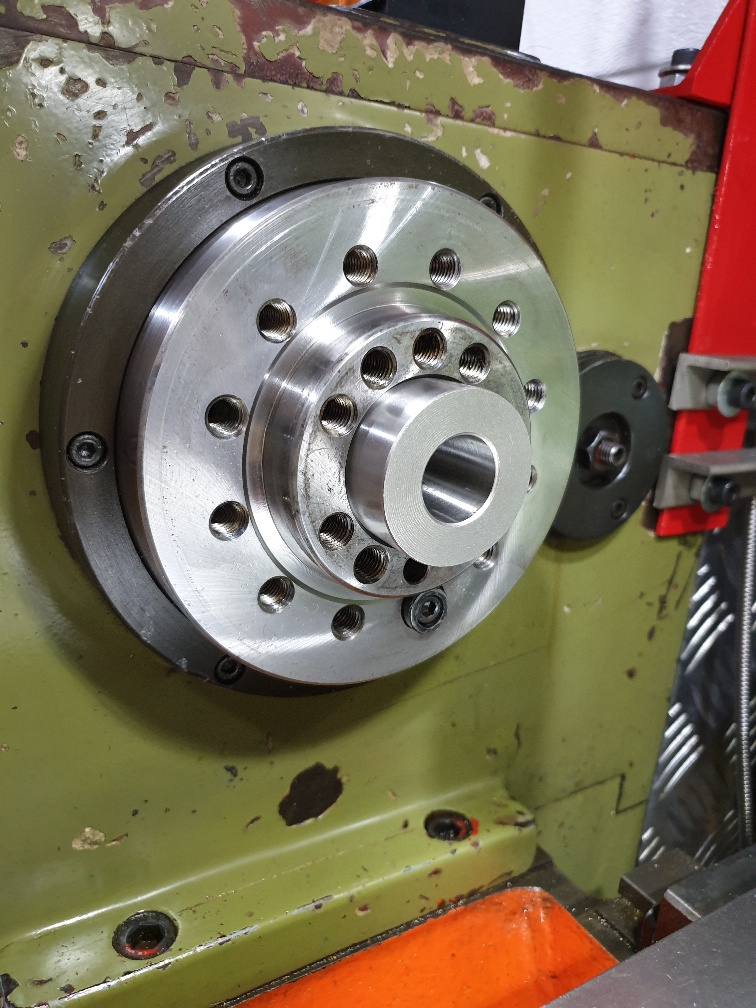

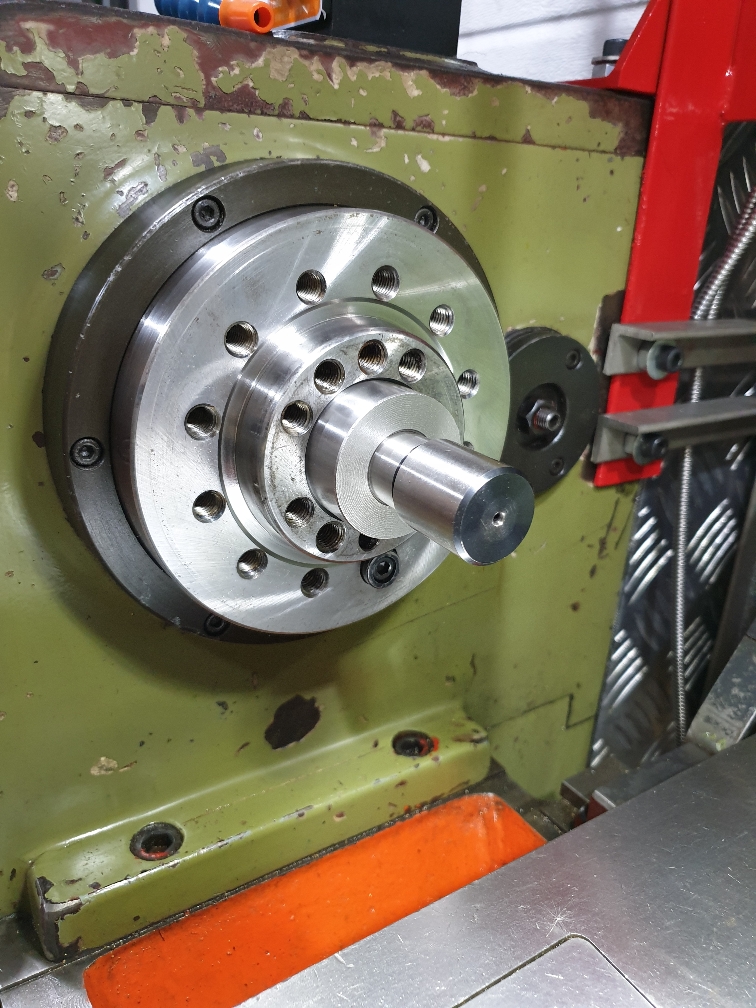

Peter, which was too small, the sleeve or the internal taper. It is normal for a sleeve to stick out a bit from the spindle. Or did the MT5 sleeve go too far into the spindle?Well its not a MT5. Bought one and it's too small. Back to the drawing board.

Sent from my SM-N960F using Tapatalk

Based on calculation, a good portion of an MT5 sleeve should fit in the spindle but with some sticking out.