-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coop's Canedy-Otto Cincinnati Royal 18

- Thread starter CoopVA

- Start date

- Joined

- Sep 28, 2013

- Messages

- 4,306

you're welcome  Just use the smallest prying tool that'll do the job and you'll be fine. You can even use the same tool to dig the gunk out of the bearings so that the degreaser works faster. Just make sure to flush it all out afterwards (hence the WD40 rinse). I've done it a bunch of time on sealed bearings on my bikes. It's not quite as good as new bearings as they don't last quite as long before they get rough again, but that is with being pounded, twisted and immersed in gritty water on a regular basis!

Just use the smallest prying tool that'll do the job and you'll be fine. You can even use the same tool to dig the gunk out of the bearings so that the degreaser works faster. Just make sure to flush it all out afterwards (hence the WD40 rinse). I've done it a bunch of time on sealed bearings on my bikes. It's not quite as good as new bearings as they don't last quite as long before they get rough again, but that is with being pounded, twisted and immersed in gritty water on a regular basis!

- Joined

- Feb 1, 2014

- Messages

- 339

I got the spindle out of the quill with the new 20 ton shop press I got at the local HF store. Now I need to go get a blind bearing puller to get the bearings out of the quill.The bearings are shielded with metal, not sealed with rubber. Ive seen videos were the shield was pried out like you are describing Matt. I will try it. The bearings in the quill are Federal 1205 RR... i found those to be fairly common. The bearings on the pulley stack are New Departure 1206. I found an equivalent Federal 1206 M. So if I mess up the shields, I feel good about getting new bearings, which I might do anyway.

- Joined

- Sep 28, 2013

- Messages

- 4,306

Very nice indeed. Those Jacobs chicks really scrub up well too

- Joined

- Feb 1, 2014

- Messages

- 339

- Joined

- Sep 28, 2013

- Messages

- 4,306

great job, that must have felt awesome! I went from a hand drill to a WT 15in and it was similarly impressive. I assume it's predecessor is on the ground behind it? Anything left to do or is it all done? Don't forget the "money" shots

- Joined

- Feb 1, 2014

- Messages

- 339

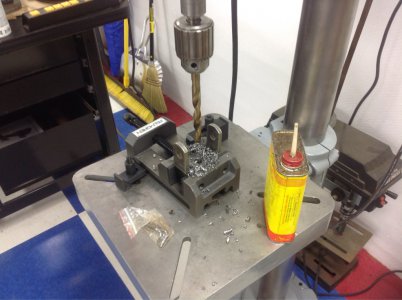

Thanks Matt. It was a great feeling! She ran smooth and quiet too! The VFD made more noise than the drill...

Still have to clean up and mount the plates and make some new handles. Other than that, she's done. I'll get some more pics up this weekend.

Still have to clean up and mount the plates and make some new handles. Other than that, she's done. I'll get some more pics up this weekend.