- Joined

- Jul 18, 2017

- Messages

- 400

Hi Guys,

As many of you know, I recently acquired the 2J Bridgeport mill at a great price. I wasn't looking to buy it, but couldn't resist not jumping on the deal. So, this mill is sitting in my garage when I got an offer to get a vintage Diamond horizontal mill and an 18" Craftsman Bandsaw with gearbox for free. These two items were picked up by my friend, and he is holding them on his lot until I tell him I am made room in my 1 car garage for them.

Since I already had a R8 cartridge milling spindle that I picked up off ebay for cheap, I was planning to one day make a vertical milling head with it to use on the Diamond horizontal mill.

I plan on making small tools to sell on ebay, including gears and various adapters. I tossed around the idea of selling the Bridgeport mill should my vertical milling head work well on the Diamond mill since it might be like owning a Ferrari when I am homeless, and just need a car to drive around my neighborhood, lol.

I have a nice 15" Atlas 73 floor drill press. It is the super old kind where there is no rack elevation crank to raise/lower the table. To move the table, I have to loosen the table's column collar and move the table with my arms/hands, and then tighten the collar at the chosen height for the table.

If I kept the Bridgeport mill, I could be happy with having only this Atlas for basic holes. I could even ad an additional pulley to slow its speed should I want to use its original Atlas motor instead of using an Inverter duty motor with and VFD. Then, if I needed to make holes beyond the Atlas' capabilities, I would just drill using the mill.

If I didn't keep the Bridgeport, I question if my 15" old 1/3 hp drill were powerful enough.

Given that I have a weakness for going overkill with how much power I need, I responded to a craigslist ad for a much beefier 17" Delta drill press from a company that was simply getting rid of a bunch of machines that they didn't need. They only wanted $100 for the drill. The only catch, in my mind was how disgustingly filthy the drill is. I will post a few pics in this posting.

I emailed the company's owner, and honestly explained that I responded to his ad for the drill because I wanted a heavy duty drill for a machine shop that I am building in my garage that I hope to share with people who might not have the means to ever have the chance to do some metalworking. I also told him how I misplaced my debit card and had no access to cash, but that I could paypal him. He was cool about it and told me he'd be fine with paypal. He then told me to contact his assistant to setup a time to stop by.

When I contacted his assistant Maryann, she told me that the owner wants to do whatever he can to help me out since it means a lot that I would help people with his machines. Maryann told me that the drills they had were very heavy and that they can deliver it to my home for free. I was a little surprised by their offer, and I said thanks. Maryann then told me that the warehouse guy, Curt, knew all about me, and would be waiting for me to stop by.

Ok, now this is beginning to sound weird to me how welcoming everyone was. It's not like I am starting a non-profit organization to teach metalworking to starving children, lol.

Then, when I arrived at their warehouse, I walked towards the back where they had 4 drill presses for sale. 2 were vintage 15" floor drill presses (Delta and Powermatic) that looked ready to go to work, and was not filthy like the 2 larger 17" drill presses. However, I really wanted the 17" Delta. It was huge, and it had a nice hand crank to elevate the table. The two 17" drill both had original Delta 3/4 hp motors, hydraulic quill feeds, and both had a pneumatic vise attached to the table.

Here are some pics of the 17" drill:

I felt like I had to get this drill since I probably wont' get a chance to buy such a big drill at the price offered. The column is 3.5" wide, and the bottom column base is 18.5"w x 26"d. This drill really reeked of testosterone ;-)

Then, the warehouse guy, Curt told me that since I am helping people, he'll give me a second drill for FREE! Now, I was very shocked at the offer. Since I have seen big floor drill presses on Craigslist being sold for $500-$1000 here in the Bay Area, I said I'll take the 2 big drills. Curt then asked if I were sure since the smaller ones are lighter. I didn't want to tell him I already had a 15" Atlas at home, and just said that the larger ones are harder to find/have.

Then, Curt points to a machine in the corner of the warehouse and tells me that the owner said I might be interested in it since I am making a metalworking shop. The machine was a horizontal metal bender that came with a ton of dies. I have never heard of such a machine. I asked how much, and Curt says he'll let me have it for $200. I then told Curt that I'd have to research this machine over the weekend (it was Friday) before I can say yes or no.

Anyways, below are pics of the bender. it looks like it is powered via the compressor. I honestly don't know how I would need such a machine that bends such narrow pieces. I am hoping you guys can give me feedback if this machine would be of any use to me. I saw on ebay someone selling the same Richards Multiform Bender (non-pneumatic) for $2000 plus shipping.

Here is a link to a similiar machine. They refer to it on the webpage as a power bender:

http://www.jarichards.com/

Here's a link to a fancy new horizontal bender that makes the machine look pretty awesome:

Back to my warehouse story.....

Then, a female employee tells me that her mom is MaryAnn, and that she (the daughter) could use her truck to deliver the drills Sunday. I asked her what machinery she had to lift the 300+ lbs drills, and she replied, "My husband." Wow, he must be one strong dude!

I tell her thanks, and that I need to decide if the drills are going into my garage or into my storage unit until I have room for them in the garage. I am actually going to just keep one and clean up the other to sell eventually.

So, to summarize this long post, I just wanted to know:

Am I am giving myself more headache than needed by getting a 2nd equally filthy drill when the drills are so heavy?

Should I get a smaller 15" floor drill press that is ready to be sold?

.Is it insane to have 2 drill presses? For some reason, I really love my 15" Atlas drill but also want a bigger one.

Would I be better off removing the hydraulic quill feed set up off the Delta?

Should I pass on the metal bender?

Do you think I could use the horizontal bender's ram to work as a metal shaper?

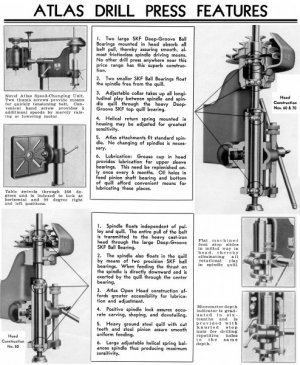

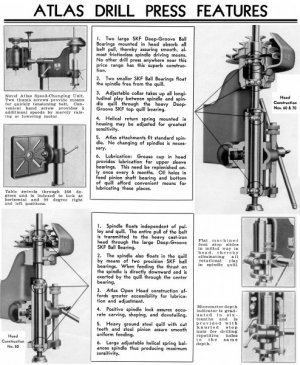

For the heck of it, since I am posting so many pics anyways, here are pics of sheets with the Atlas and Delta drill specs/features:

Atlas

Delta

My beloved Atlas

Thanks a lot,

Susan

As many of you know, I recently acquired the 2J Bridgeport mill at a great price. I wasn't looking to buy it, but couldn't resist not jumping on the deal. So, this mill is sitting in my garage when I got an offer to get a vintage Diamond horizontal mill and an 18" Craftsman Bandsaw with gearbox for free. These two items were picked up by my friend, and he is holding them on his lot until I tell him I am made room in my 1 car garage for them.

Since I already had a R8 cartridge milling spindle that I picked up off ebay for cheap, I was planning to one day make a vertical milling head with it to use on the Diamond horizontal mill.

I plan on making small tools to sell on ebay, including gears and various adapters. I tossed around the idea of selling the Bridgeport mill should my vertical milling head work well on the Diamond mill since it might be like owning a Ferrari when I am homeless, and just need a car to drive around my neighborhood, lol.

I have a nice 15" Atlas 73 floor drill press. It is the super old kind where there is no rack elevation crank to raise/lower the table. To move the table, I have to loosen the table's column collar and move the table with my arms/hands, and then tighten the collar at the chosen height for the table.

If I kept the Bridgeport mill, I could be happy with having only this Atlas for basic holes. I could even ad an additional pulley to slow its speed should I want to use its original Atlas motor instead of using an Inverter duty motor with and VFD. Then, if I needed to make holes beyond the Atlas' capabilities, I would just drill using the mill.

If I didn't keep the Bridgeport, I question if my 15" old 1/3 hp drill were powerful enough.

Given that I have a weakness for going overkill with how much power I need, I responded to a craigslist ad for a much beefier 17" Delta drill press from a company that was simply getting rid of a bunch of machines that they didn't need. They only wanted $100 for the drill. The only catch, in my mind was how disgustingly filthy the drill is. I will post a few pics in this posting.

I emailed the company's owner, and honestly explained that I responded to his ad for the drill because I wanted a heavy duty drill for a machine shop that I am building in my garage that I hope to share with people who might not have the means to ever have the chance to do some metalworking. I also told him how I misplaced my debit card and had no access to cash, but that I could paypal him. He was cool about it and told me he'd be fine with paypal. He then told me to contact his assistant to setup a time to stop by.

When I contacted his assistant Maryann, she told me that the owner wants to do whatever he can to help me out since it means a lot that I would help people with his machines. Maryann told me that the drills they had were very heavy and that they can deliver it to my home for free. I was a little surprised by their offer, and I said thanks. Maryann then told me that the warehouse guy, Curt, knew all about me, and would be waiting for me to stop by.

Ok, now this is beginning to sound weird to me how welcoming everyone was. It's not like I am starting a non-profit organization to teach metalworking to starving children, lol.

Then, when I arrived at their warehouse, I walked towards the back where they had 4 drill presses for sale. 2 were vintage 15" floor drill presses (Delta and Powermatic) that looked ready to go to work, and was not filthy like the 2 larger 17" drill presses. However, I really wanted the 17" Delta. It was huge, and it had a nice hand crank to elevate the table. The two 17" drill both had original Delta 3/4 hp motors, hydraulic quill feeds, and both had a pneumatic vise attached to the table.

Here are some pics of the 17" drill:

I felt like I had to get this drill since I probably wont' get a chance to buy such a big drill at the price offered. The column is 3.5" wide, and the bottom column base is 18.5"w x 26"d. This drill really reeked of testosterone ;-)

Then, the warehouse guy, Curt told me that since I am helping people, he'll give me a second drill for FREE! Now, I was very shocked at the offer. Since I have seen big floor drill presses on Craigslist being sold for $500-$1000 here in the Bay Area, I said I'll take the 2 big drills. Curt then asked if I were sure since the smaller ones are lighter. I didn't want to tell him I already had a 15" Atlas at home, and just said that the larger ones are harder to find/have.

Then, Curt points to a machine in the corner of the warehouse and tells me that the owner said I might be interested in it since I am making a metalworking shop. The machine was a horizontal metal bender that came with a ton of dies. I have never heard of such a machine. I asked how much, and Curt says he'll let me have it for $200. I then told Curt that I'd have to research this machine over the weekend (it was Friday) before I can say yes or no.

Anyways, below are pics of the bender. it looks like it is powered via the compressor. I honestly don't know how I would need such a machine that bends such narrow pieces. I am hoping you guys can give me feedback if this machine would be of any use to me. I saw on ebay someone selling the same Richards Multiform Bender (non-pneumatic) for $2000 plus shipping.

Here is a link to a similiar machine. They refer to it on the webpage as a power bender:

http://www.jarichards.com/

Here's a link to a fancy new horizontal bender that makes the machine look pretty awesome:

Back to my warehouse story.....

Then, a female employee tells me that her mom is MaryAnn, and that she (the daughter) could use her truck to deliver the drills Sunday. I asked her what machinery she had to lift the 300+ lbs drills, and she replied, "My husband." Wow, he must be one strong dude!

I tell her thanks, and that I need to decide if the drills are going into my garage or into my storage unit until I have room for them in the garage. I am actually going to just keep one and clean up the other to sell eventually.

So, to summarize this long post, I just wanted to know:

Am I am giving myself more headache than needed by getting a 2nd equally filthy drill when the drills are so heavy?

Should I get a smaller 15" floor drill press that is ready to be sold?

.Is it insane to have 2 drill presses? For some reason, I really love my 15" Atlas drill but also want a bigger one.

Would I be better off removing the hydraulic quill feed set up off the Delta?

Should I pass on the metal bender?

Do you think I could use the horizontal bender's ram to work as a metal shaper?

For the heck of it, since I am posting so many pics anyways, here are pics of sheets with the Atlas and Delta drill specs/features:

Atlas

Delta

My beloved Atlas

Thanks a lot,

Susan

Last edited:

Normally I would encourage buying cool toys, but having room to play with them is important also.

Normally I would encourage buying cool toys, but having room to play with them is important also.