- Joined

- Dec 12, 2021

- Messages

- 82

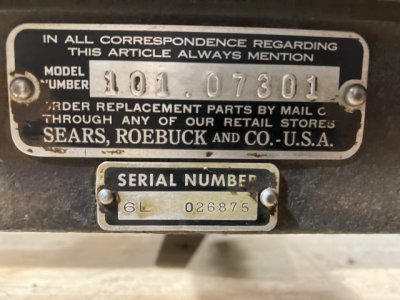

A friend gifted two machines, a Craftsman 101 and a mystery machine. I want to determine how much of the Craftsman 101 is missing and or broken and after that figure out what to do with it. The images that start with C101 are for the Craftsman machine.

C101 issues:

1. Missing lead screw, and support bearings.

2. Carriage missing gears, handle, and other parts. Half nuts and indicator are ok. There is a shaft that fits the hole in the, but not sure if that is correct.

3. Not sure that the cross slide belongs with the C101 or the mystery machine.

4. There is no tool post, but confused about the odd clamp where a tool post should go. Does a cross slide mount to that?

5. Banjo and some gears to drive the lead screw, but is all the gearing there?

6. I got a box of parts which could fit either either machine.

7. Head stock OK, but front bearing appears to have been brazed and it has about 15 - 20 mills of play.

8. Pully and clutch system is missing and no motor.

Mystery machine:

Mx.jpeg is a side view. I has a lead screw, but no drive. There are no half nuts. The carriage had two bars screwed to it (seen in center of picture) and a homemade chip guard (left in picture) was attached. Something like a tail stock is seen on the left. It has a belt driven pulley to drive a rotating shaft. I'm not sure what that is actually for. There is a headstock which may or may not be associated with the mystery machine. Note that the bottom of this headstock has been ground off flat - well butchered actually. It can't mount to the mystery bed as is. Maybe the thought was to mount this head stock on the C101 because of the bearings? Except for the base, the headstock is ok.

Can anyone ID the mystery machine?

My friend said that he had paperwork for me, but I don't know any more than that. I may get that tomorrow.

In the end, I have a couple of choices. Restore them, adapt the parts to a home-brew machine(s), or find them another home.

Thanks in advance for any feedback and advice.

Spajo

C101 issues:

1. Missing lead screw, and support bearings.

2. Carriage missing gears, handle, and other parts. Half nuts and indicator are ok. There is a shaft that fits the hole in the, but not sure if that is correct.

3. Not sure that the cross slide belongs with the C101 or the mystery machine.

4. There is no tool post, but confused about the odd clamp where a tool post should go. Does a cross slide mount to that?

5. Banjo and some gears to drive the lead screw, but is all the gearing there?

6. I got a box of parts which could fit either either machine.

7. Head stock OK, but front bearing appears to have been brazed and it has about 15 - 20 mills of play.

8. Pully and clutch system is missing and no motor.

Mystery machine:

Mx.jpeg is a side view. I has a lead screw, but no drive. There are no half nuts. The carriage had two bars screwed to it (seen in center of picture) and a homemade chip guard (left in picture) was attached. Something like a tail stock is seen on the left. It has a belt driven pulley to drive a rotating shaft. I'm not sure what that is actually for. There is a headstock which may or may not be associated with the mystery machine. Note that the bottom of this headstock has been ground off flat - well butchered actually. It can't mount to the mystery bed as is. Maybe the thought was to mount this head stock on the C101 because of the bearings? Except for the base, the headstock is ok.

Can anyone ID the mystery machine?

My friend said that he had paperwork for me, but I don't know any more than that. I may get that tomorrow.

In the end, I have a couple of choices. Restore them, adapt the parts to a home-brew machine(s), or find them another home.

Thanks in advance for any feedback and advice.

Spajo