- Joined

- Jun 28, 2021

- Messages

- 142

Count me clueless when it comes to CNC tooling.

I have need to turn, or more accurately, have turned a 25° thread in some tiny brass parts. The CNC shop I have found that is interested in this job can't find a source for a threading tool with this oddball thread angle. My question is -- how do you do this custom profile when using a CNC machine? With my manual machines I would just grind a tool bit as best I could, set it up as best I could and go for it. Since I need hundreds of these, doing them manually is not a good option for either my time, my back, or my sanity.

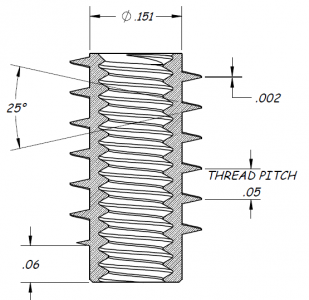

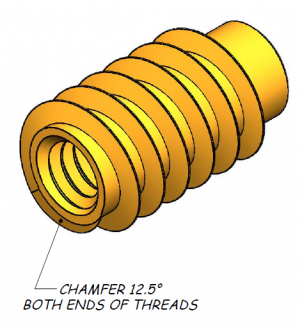

This is what the part looks like;

The part is 3/8" long. It is a miniature brass insert for use in wood. The internal thread will be either #4-40 or #6-32. The body of the insert is smaller than anything I have found that is commercially available. The external thread is a copy of what is used in the larger inserts that are commercially available.

Any ideas?

I have need to turn, or more accurately, have turned a 25° thread in some tiny brass parts. The CNC shop I have found that is interested in this job can't find a source for a threading tool with this oddball thread angle. My question is -- how do you do this custom profile when using a CNC machine? With my manual machines I would just grind a tool bit as best I could, set it up as best I could and go for it. Since I need hundreds of these, doing them manually is not a good option for either my time, my back, or my sanity.

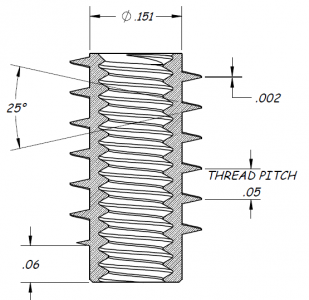

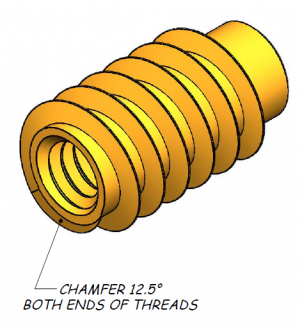

This is what the part looks like;

The part is 3/8" long. It is a miniature brass insert for use in wood. The internal thread will be either #4-40 or #6-32. The body of the insert is smaller than anything I have found that is commercially available. The external thread is a copy of what is used in the larger inserts that are commercially available.

Any ideas?

Have you looked into rivnuts or nutserts ? Not sure Keenserts are sold that small but that would be another option .

Have you looked into rivnuts or nutserts ? Not sure Keenserts are sold that small but that would be another option .