-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Delta Milwaukee 12” disc sander

- Thread starter tcweb

- Start date

- Joined

- Apr 23, 2018

- Messages

- 6,570

I don't know if mine is a 12" or a 14", but it's a 1 hp similar to yours. On mine, the face plate is fixed with a set screw to a flat ground on the motor shaft. It doesn't care which direction it runs, but my preference is counterclockwise. I'd just reverse the wiring rather than reversing the motor, less effort in the end for the same result.

The table is another thing. I use a square (machinist's) or protractor to set mine, because right angles are usually what I'm working to. You could shim the motor so the table protractor scale reads accurately. Me, I don't put much faith in those lines and slotted hold-downs, so I am sticking to my square.

That is a beautiful motor, by the way. Looks nice inside and out.

The table is another thing. I use a square (machinist's) or protractor to set mine, because right angles are usually what I'm working to. You could shim the motor so the table protractor scale reads accurately. Me, I don't put much faith in those lines and slotted hold-downs, so I am sticking to my square.

That is a beautiful motor, by the way. Looks nice inside and out.

- Joined

- May 25, 2016

- Messages

- 181

Greg, I don’t see how the brushes can be rotated other than 180*.

There are two screws in the bell housing that seem to hold the brush assembly in place. Of course rotating it 180 would require pulling the motor apart.

Is this normal/expected?

Tom

There are two screws in the bell housing that seem to hold the brush assembly in place. Of course rotating it 180 would require pulling the motor apart.

Is this normal/expected?

Tom

- Joined

- Dec 15, 2018

- Messages

- 787

The only one I wanted to reverse was made with the brush holders fixed to the bell, so no go there.

From what I gather it requires a 90 degree rotation of the brushes to shift the fields.

Found a video of a rebuild of a Delta motor, similar to yours. Might give some insight.

Greg

From what I gather it requires a 90 degree rotation of the brushes to shift the fields.

Found a video of a rebuild of a Delta motor, similar to yours. Might give some insight.

Greg

- Joined

- Apr 23, 2018

- Messages

- 6,570

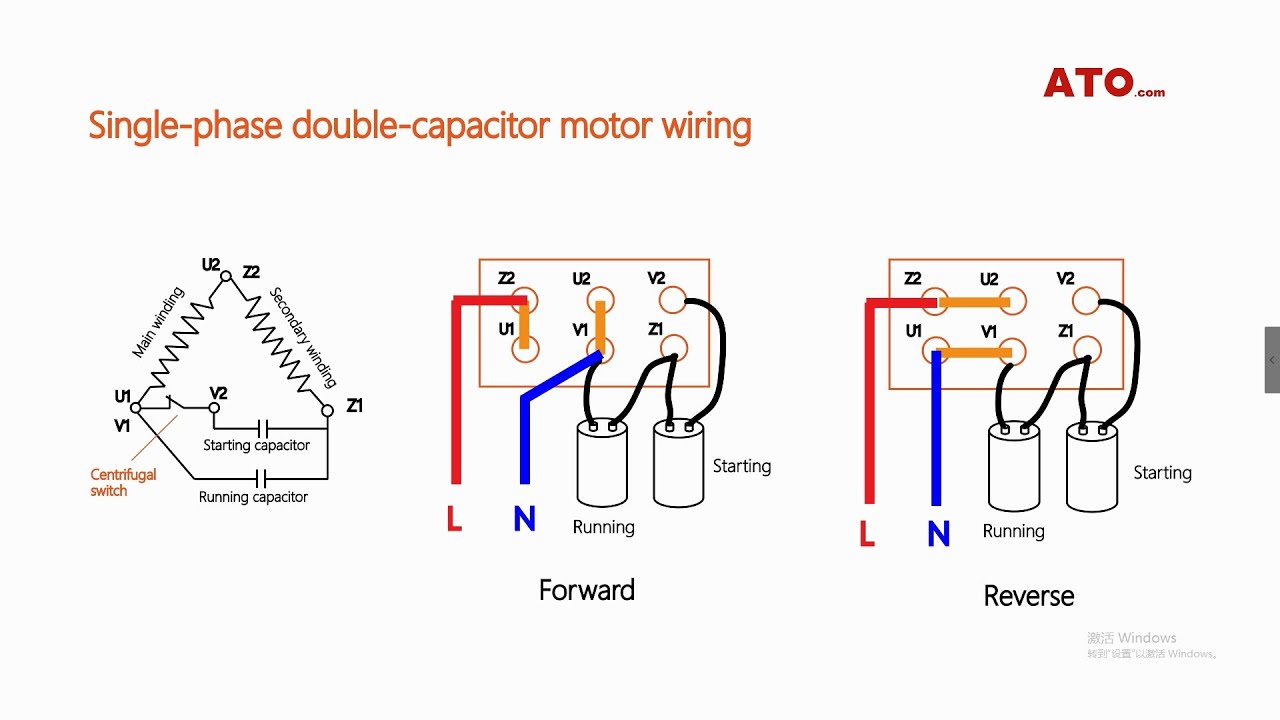

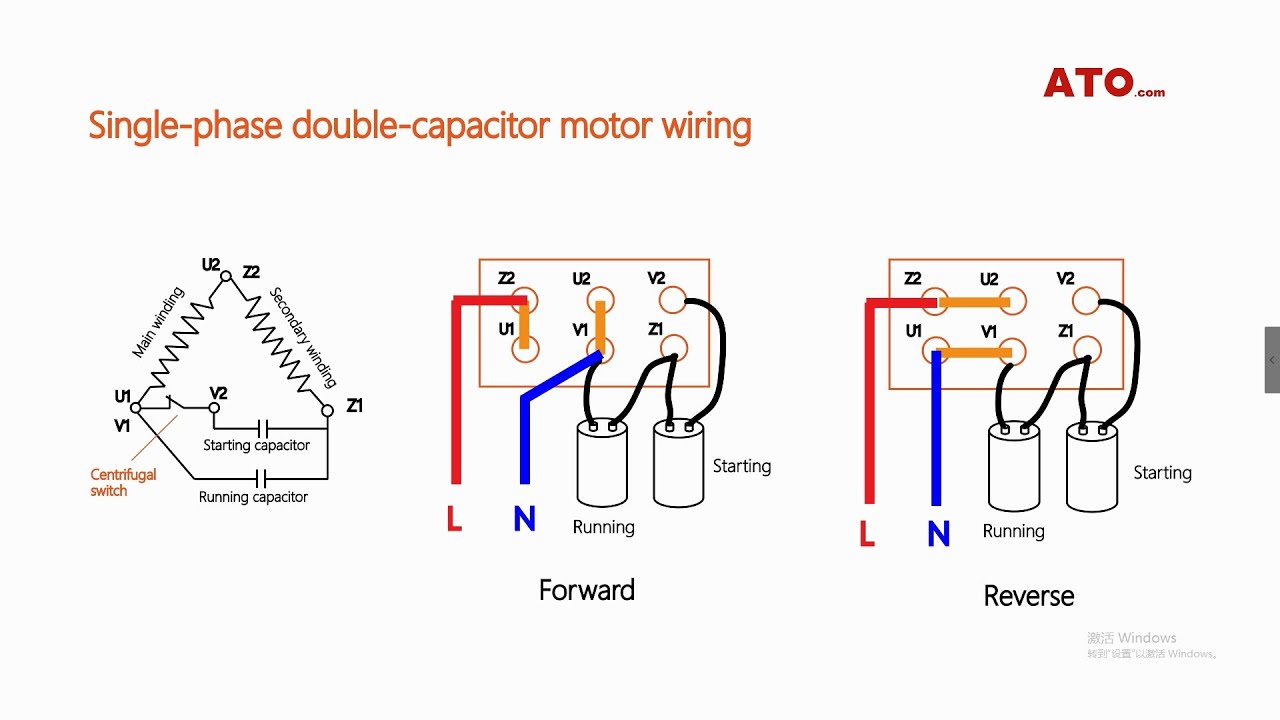

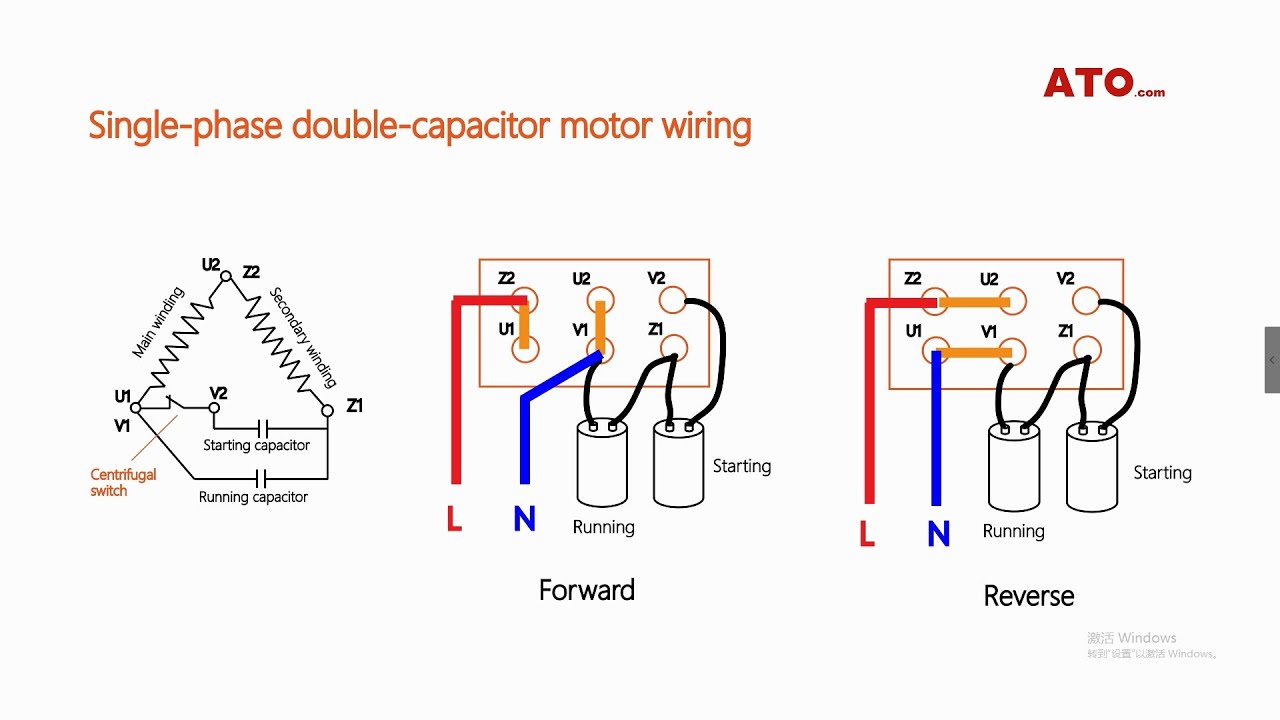

Huh, you know, being wrong is part of the hobby for me, but I thought reversing split phase motors was well below rocket surgery. And I am no wizard when it comes to electrical distro, I'm just barely functional without access to references.

For instance, the 90 year old GE plain-bearing motor on my Atlas lathe was reversible by adding a drum switch or even a DPDT toggle switch to create this circuit:

For instance, the 90 year old GE plain-bearing motor on my Atlas lathe was reversible by adding a drum switch or even a DPDT toggle switch to create this circuit:

- Joined

- May 25, 2016

- Messages

- 181

Pontiac, this is not a capacitor start motor.Huh, you know, being wrong is part of the hobby for me, but I thought reversing split phase motors was well below rocket surgery. And I am no wizard when it comes to electrical distro, I'm just barely functional without access to references.

For instance, the 90 year old GE plain-bearing motor on my Atlas lathe was reversible by adding a drum switch or even a DPDT toggle switch to create this circuit:

- Joined

- May 25, 2016

- Messages

- 181

F350, you da man. Your google Fu was strong. That is exactly what i needed to see. The two screws on the front bell just clamp down the brush assembly. That’s how it’s rotated to change the rotation…

Thanks!

Thanks!

- Joined

- May 25, 2016

- Messages

- 181

As an FYI, there are markings inside the brush cover. I see "L | R"

and an index mark on the bell housing.

So If you rotate the brushes to "L", it spins counterclockwise. Rotate to "R" and it spins clockwise.

Too easy, once you see it. My motor had enough crap in there the first time I opened it up, I didn't notice the markings.

-Tom

and an index mark on the bell housing.

So If you rotate the brushes to "L", it spins counterclockwise. Rotate to "R" and it spins clockwise.

Too easy, once you see it. My motor had enough crap in there the first time I opened it up, I didn't notice the markings.

-Tom