- Joined

- Sep 29, 2017

- Messages

- 2,251

Hi guys.

You know how you never have enough toolholders?...............................so I made 10

I guess it will still not be enough, but it will make a big difference. I started with a piece of mild steel 600mm×45mm×115mm and machined the sides to get it parallel.

I then milled out the middle to depth for the clamping section,

but.............something went wrong. I milled one half and when I started the other half, I noticed that on the first half the mill must have started to come loose an dug in slowly so it went deeper than intended. It would not have made a difference, but I just couldn't leave it like that and after chopping the material up in the right lengths, I welded it up and machined it again. Thats just the way it had to be done. I then had to cross my "T's" (get it?), by using the 8mm T slott cutter,but I completely forgot to take pics of this.

The next blunder was not mine and I was not happy about it at all. The long piece of material had to be cut up in the correct lengths of approximately 58mm. I marked it out and took it to a local engineering shop to chop it up for me on the radial bandsaw. This is what I got back.

Check the three on the right. Not square at all.

The operator did not check his work and work pride was not on his agenda. I showed the owners son and he was nice enough to not charge me.

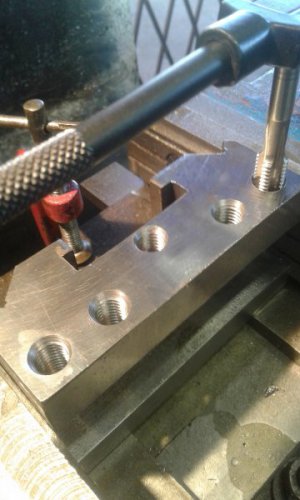

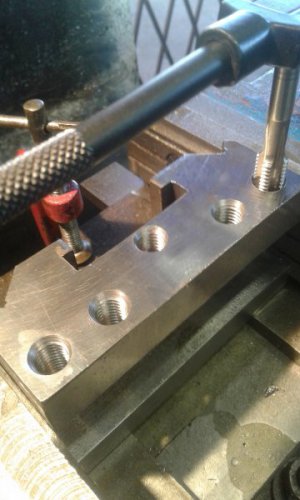

After I fixed my blunder by welding it up and machining it down, I took some of rhe blocks to the lathe to drill appropriate holes for some of the boring bars and the rest I milled for the square toolholders.

The 12mm 4fluit mill performed nice at a 12mm depth of cut.

Then it was time to do the v-grooves. I did this by using my new digital protractor or inclinometer wich I bought via eBay, to set my mill at 45degr. to make the 90degr.v-grooves. What a handy little instrument to have.

On to the relief grooves in the v-groove wich was done with a 3mm endmill.

Most of the work was about done so I cleaned up all the remaining surfaces with a flycutter.

The last parts I had to make was the height adjusters. I made them out of EN8.

Well guys this was fun,it took me a long time,because I had to do it between jobs and there is a lot of machining involved plus the mishaps of course. I will dip my hand in nickel electroplating and nickel plate them to prevent it fro rusting.

Thanks for viewing.

Michael

You know how you never have enough toolholders?...............................so I made 10

I guess it will still not be enough, but it will make a big difference. I started with a piece of mild steel 600mm×45mm×115mm and machined the sides to get it parallel.

I then milled out the middle to depth for the clamping section,

but.............something went wrong. I milled one half and when I started the other half, I noticed that on the first half the mill must have started to come loose an dug in slowly so it went deeper than intended. It would not have made a difference, but I just couldn't leave it like that and after chopping the material up in the right lengths, I welded it up and machined it again. Thats just the way it had to be done. I then had to cross my "T's" (get it?), by using the 8mm T slott cutter,but I completely forgot to take pics of this.

The next blunder was not mine and I was not happy about it at all. The long piece of material had to be cut up in the correct lengths of approximately 58mm. I marked it out and took it to a local engineering shop to chop it up for me on the radial bandsaw. This is what I got back.

Check the three on the right. Not square at all.

The operator did not check his work and work pride was not on his agenda. I showed the owners son and he was nice enough to not charge me.

After I fixed my blunder by welding it up and machining it down, I took some of rhe blocks to the lathe to drill appropriate holes for some of the boring bars and the rest I milled for the square toolholders.

The 12mm 4fluit mill performed nice at a 12mm depth of cut.

Then it was time to do the v-grooves. I did this by using my new digital protractor or inclinometer wich I bought via eBay, to set my mill at 45degr. to make the 90degr.v-grooves. What a handy little instrument to have.

On to the relief grooves in the v-groove wich was done with a 3mm endmill.

Most of the work was about done so I cleaned up all the remaining surfaces with a flycutter.

The last parts I had to make was the height adjusters. I made them out of EN8.

Well guys this was fun,it took me a long time,because I had to do it between jobs and there is a lot of machining involved plus the mishaps of course. I will dip my hand in nickel electroplating and nickel plate them to prevent it fro rusting.

Thanks for viewing.

Michael