I have been working on this for about a month now and finally finished it. What can I say, I'm sloooooow.

* I can not claim any originality in design on this except where I deviated from the plans .

A gentleman by the name of Pat Loop was the designer and builder of the original. I am indebted to him for his design.

*As I don't know the copy right status of the plans, I am not posting tem here. If anyone knows if the plans are made to be freely distributed let me know and I will post them.

*I found the plans on the web about 2005 and just now worked up the courage to try and build it.

* Here is a shot of the parts all laid out.

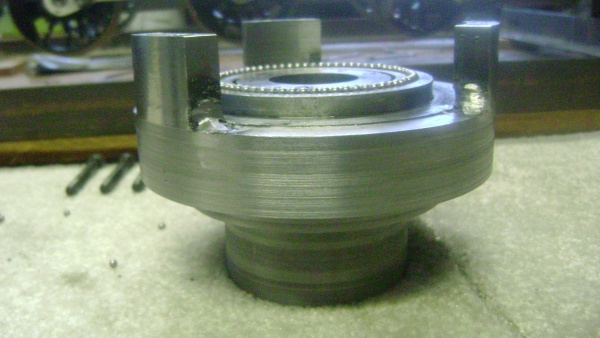

* The first thing I made was the Collet holder. It is mild steel

*The 3 ears you see sticking up were supposed to be made as one pice with the holder,but as there is a rather large groove for the protruding ridge on the collet nut and I was afraid that I would have trouble machining it. As it turned out I was right as I had trouble just trying to machine the .060 deep bearing grooves. So I made the ears* from 3 seperate pieces and after the back plate was made I bolted it all up and welded them onto the collet holder amd machined them. Interupted cuts, Yikes!! But I got it done.

*The smaller dia. that sticks out the front was made as a seperate piece also as I didn't have a large enough piece of stock to machine it in one go. I machined a recess about .250 deep in the 5" dia piece and then made the smaller piece an interference fit and pressed it in, then bolted it with 1/4-20 cap socket head cap srews, it will never come off.

* The next piece was the back plate. It's made out of cast iron.

I made a copy of my spindle threads to use as a gauge when I threaded the back plate so it would be a good fit. (Sorry no pic of it) Actually I made 2 but screwed up the first one.

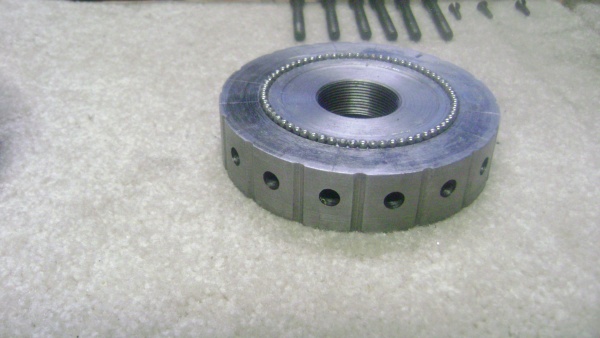

*Next up was the collet nut. It's mild steel and I used a collet as a thread gauge to get a good fit here also.

* *Here you can see the ridge I refered to earlier.

* I drilled 1/4 in holes around it to use a tommy bar for tightening up the collet and also* used a 3/16 ball end mill for finger holds to aid in starting the nut on the collet.

* *This piece here's only function , as far as I can tell, is to hold the key that stops the collet from rotating. Look closely and you can see the key at the bottom on the inside dia. It is held in by 3 countersunk 6-32 allen head cap screws.

*In these shots you can see the over 260 1/8th in chrome steel balls that make up the bearings. There are about 134 balls on the collet holder part, then the collet nut is put on and another approx 134 balls are put on with a little litium grease for lube.

Then everything was matched up and bolted together with 6 1/4-20 x 2in SHCS.

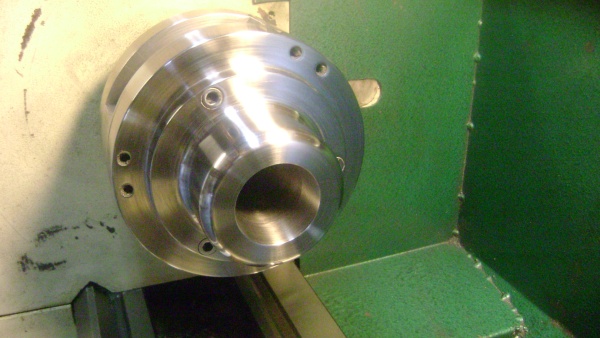

* I mounted it on the lathe and clocked it with a dial indicator and had about .002 total indicated run out. I loosened the screws and gave it a little love tap with a plastic hammer and it showed .0005 TIR. I tightened everything up again and put a 3/16 collet in with a 3/16 end mill in shank first and left some of the sha exposed so it could use a dial test indicator this time and it showed .0005 TI.* I called it darn good and started to make it shiny. After about 3 hours work with files and emery cloth this is how it came out.

*Without a collet.

*With a collet.

I did some web searching and found out the Chuck was featured in the old "Projects in Metal " Magazine, which I believe is now "Home Shop Machinist".

* The issue is Volume 1 No. 3 - June 1988.

Ron

* I can not claim any originality in design on this except where I deviated from the plans .

A gentleman by the name of Pat Loop was the designer and builder of the original. I am indebted to him for his design.

*As I don't know the copy right status of the plans, I am not posting tem here. If anyone knows if the plans are made to be freely distributed let me know and I will post them.

*I found the plans on the web about 2005 and just now worked up the courage to try and build it.

* Here is a shot of the parts all laid out.

* The first thing I made was the Collet holder. It is mild steel

*The 3 ears you see sticking up were supposed to be made as one pice with the holder,but as there is a rather large groove for the protruding ridge on the collet nut and I was afraid that I would have trouble machining it. As it turned out I was right as I had trouble just trying to machine the .060 deep bearing grooves. So I made the ears* from 3 seperate pieces and after the back plate was made I bolted it all up and welded them onto the collet holder amd machined them. Interupted cuts, Yikes!! But I got it done.

*The smaller dia. that sticks out the front was made as a seperate piece also as I didn't have a large enough piece of stock to machine it in one go. I machined a recess about .250 deep in the 5" dia piece and then made the smaller piece an interference fit and pressed it in, then bolted it with 1/4-20 cap socket head cap srews, it will never come off.

* The next piece was the back plate. It's made out of cast iron.

I made a copy of my spindle threads to use as a gauge when I threaded the back plate so it would be a good fit. (Sorry no pic of it) Actually I made 2 but screwed up the first one.

*Next up was the collet nut. It's mild steel and I used a collet as a thread gauge to get a good fit here also.

* *Here you can see the ridge I refered to earlier.

* I drilled 1/4 in holes around it to use a tommy bar for tightening up the collet and also* used a 3/16 ball end mill for finger holds to aid in starting the nut on the collet.

* *This piece here's only function , as far as I can tell, is to hold the key that stops the collet from rotating. Look closely and you can see the key at the bottom on the inside dia. It is held in by 3 countersunk 6-32 allen head cap screws.

*In these shots you can see the over 260 1/8th in chrome steel balls that make up the bearings. There are about 134 balls on the collet holder part, then the collet nut is put on and another approx 134 balls are put on with a little litium grease for lube.

Then everything was matched up and bolted together with 6 1/4-20 x 2in SHCS.

* I mounted it on the lathe and clocked it with a dial indicator and had about .002 total indicated run out. I loosened the screws and gave it a little love tap with a plastic hammer and it showed .0005 TIR. I tightened everything up again and put a 3/16 collet in with a 3/16 end mill in shank first and left some of the sha exposed so it could use a dial test indicator this time and it showed .0005 TI.* I called it darn good and started to make it shiny. After about 3 hours work with files and emery cloth this is how it came out.

*Without a collet.

*With a collet.

I did some web searching and found out the Chuck was featured in the old "Projects in Metal " Magazine, which I believe is now "Home Shop Machinist".

* The issue is Volume 1 No. 3 - June 1988.

Ron

:man:

:man: