- Joined

- Mar 26, 2018

- Messages

- 8,410

It sure is nice to dream up an idea, go out into the shop and whip it up in less than an hour.

I found this 4" Rockwell planer-jointer on Craigslist.

I'm going through it to get it ready to use and hand over to my son. He's a starving teacher in the California school system. (proud PaPa)

I like to help him where I can.

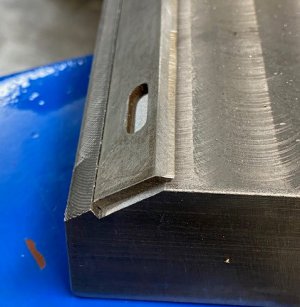

This is just a block of hot rolled steel, I put it in vinegar for 3 days to remove the thick layer of mill scale. Used the horizontal saw to cut a block a bit longer than the blades.

I then placed the block at a 35 degree angle in the Kurt vise. Used a 7/8" end mill to seat the blade into the block for a secure and repeatable position.

This will allow for the planer blades to be sharpened on my surface grinder.

I'm using a CBN wheel that puts a mirror finish on parts.

I'll just drill and tap 10-32 to hold the blades to the block.

I don't know if this is the only one in existence or if this is a common idea?? It just came to me one day.

I found this 4" Rockwell planer-jointer on Craigslist.

I'm going through it to get it ready to use and hand over to my son. He's a starving teacher in the California school system. (proud PaPa)

I like to help him where I can.

This is just a block of hot rolled steel, I put it in vinegar for 3 days to remove the thick layer of mill scale. Used the horizontal saw to cut a block a bit longer than the blades.

I then placed the block at a 35 degree angle in the Kurt vise. Used a 7/8" end mill to seat the blade into the block for a secure and repeatable position.

This will allow for the planer blades to be sharpened on my surface grinder.

I'm using a CBN wheel that puts a mirror finish on parts.

I'll just drill and tap 10-32 to hold the blades to the block.

I don't know if this is the only one in existence or if this is a common idea?? It just came to me one day.