- Joined

- Feb 1, 2018

- Messages

- 1,868

Hello everyone,

For those who don't know me, I am a Journeyman Machine Tool Rebuilder and when Hobby Machinist started, I was this forums Moderator. I answered the members questions on all things mechanical repair of machines. As you can read I have been teaching people how to scrape and rebuild machines. I would be happy to help you. Just ask. If you want to see more about me I have a web site handscraping.com

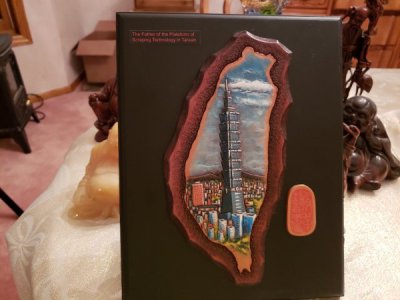

Below are Some gifts I have receive from the Machine Tool Industry of Taiwan where I have taught a total of 3 years there in 20 years of trips. The other is from students in Austria. If you read my testimonials in my website you can see one from Timken bearing and Spinner machine a new machine builder in Germany and Turkey. Plus my Hobby Machinist student on here. Makes me proud when they write about what they learned!

For those who don't know me, I am a Journeyman Machine Tool Rebuilder and when Hobby Machinist started, I was this forums Moderator. I answered the members questions on all things mechanical repair of machines. As you can read I have been teaching people how to scrape and rebuild machines. I would be happy to help you. Just ask. If you want to see more about me I have a web site handscraping.com

Below are Some gifts I have receive from the Machine Tool Industry of Taiwan where I have taught a total of 3 years there in 20 years of trips. The other is from students in Austria. If you read my testimonials in my website you can see one from Timken bearing and Spinner machine a new machine builder in Germany and Turkey. Plus my Hobby Machinist student on here. Makes me proud when they write about what they learned!

Attachments

Last edited: