Ending this post- Done, finito, Happy camper! After the new nylon cam went in, it still did not work.

30 hours later - I pulled out most of the springs, pushrods, gears, and even more the Nylon push-rod parts. Yep- Even more plastic parts in the bowels of the gear changing setup. 3D printer to the rescue again! A worn heavily grooved dowel piece was .291 diameter by .75 tall in plastic. Nice to just print that in like 10mins.

Cleaned, greased, adjusted, loved..... Runs like a new machine. Now I cannot wait to make holes in somethings

If anyone ever picks up a DGP-24 unit, Ping me... Know em' inside and out now. Whew!

PS- enjoy the manual! I've attached it here.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Doall Dgp-24 Drill Press -worn Plastic Cam. West Epoxy? Jbweld?

- Thread starter countryguy

- Start date

- Joined

- May 4, 2015

- Messages

- 3,583

I wouldn't have thought all the plastic in a gear head. And the prices they charged even used. Think ill stick to belts unless it's old old iron.

- Joined

- Oct 21, 2017

- Messages

- 504

Nice Job!

Plastic in the right application gives good durability combined with almost zero wear on mating components, Nylon is a great fit for those parts and the beauty of 3D printing them is once they are right you can start a spare set printing and do something else.

Once you get over the fascination of the 3D printer when it's running ;-)

Plastic in the right application gives good durability combined with almost zero wear on mating components, Nylon is a great fit for those parts and the beauty of 3D printing them is once they are right you can start a spare set printing and do something else.

Once you get over the fascination of the 3D printer when it's running ;-)

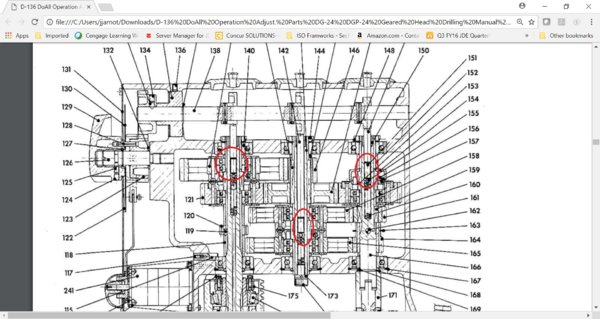

picked up a dg-24 a couple of months ago. when i went to test it out i found that all of the speeds below 400 rpm do not work. Opened up the case to check for obvious problems and everything looks fine. that is when i found your post. same machine possibly same problem. before i start tearing it apart i thought i would reach out to you for advice. do all the pushrods stay in contact with the plastic cams at all times as you turn the speed dial? the very first one on the left is not in contact with the cam, when setting the speeds below 400 rpm. if i put a pry bar in there and push the rod down the spindle will connect but I'm not sure that is the way is is supposed to work . the cam doesn't look worn at all. you said in your post that there are balls and springs and whatever in there. i assume the ball is pushed into a area that locks the spindle but i cant tell from the drawing in the manual. anyway something is broke or sticking in there and it looks like a chore to get to. tried to take the speed selector knob off by pulling out the set screw but the knob won't budge.don't want to break it by prying , that is were i a'm at present, i thought i'd ask you since you've already done this. the manual doesn't explain how the gear shift mechanism works so it's hard to figure out what might be broken . your help would be greatly appreciated. thanks pictures of the three cams, from left to right , with speed setting at 355 rpm

- Joined

- May 7, 2014

- Messages

- 776

For fusion 360 tutorials I send everyone to CNC Jon. WWW.nycnc.com YouTube as nycnc channel. You will not regret his free Fusion tutorials best jeff

I came looking for ideas on free CAD drawing software - Fusion360 - will investigate - just wanted to say - I don't own a 3D printer - and I can't see myself going that way anytime soon - but do admire the work you have done - I know that great feeling of making stuff work.

- Joined

- May 7, 2014

- Messages

- 776

ok a pic below 1 arm in sling. 1 handed reply. pardon brevity! so my #3 does the same thing as your #1 Red circle is the part that will have a worn end keeping height off kilter. I need to replace my 3D printed iten as I used a non nylon material befog I knew the 3D materials well enough. nothing fancy IU need to redo mine and will buy the right size nylon OD and cut to length Use bottle jack for motor pull out to lower/raise if you go in for other reasons very heavy. If you can get the piece out thru the top.... much easier now that I knew what the problem was. After a full tear down to learn it, I think I'll try to pull the top Cam bar, pull the bearings, pull the rod out, and then try to get it out from above. I think you cna come up via spindle for #1. #2 is a screw from bottom... (never the easy one's is it).... and my #3, if not from top, is a motor pull to pop it out from underneath.

picked up a dg-24 a couple of months ago. when i went to test it out i found that all of the speeds below 400 rpm do not work. Opened up the case to check for obvious problems and everything looks fine. that is when i found your post. same machine possibly same problem. before i start tearing it apart i thought i would reach out to you for advice. do all the pushrods stay in contact with the plastic cams at all times as you turn the speed dial? the very first one on the left is not in contact with the cam, when setting the speeds below 400 rpm. if i put a pry bar in there and push the rod down the spindle will connect but I'm not sure that is the way is is supposed to work . the cam doesn't look worn at all. you said in your post that there are balls and springs and whatever in there. i assume the ball is pushed into a area that locks the spindle but i cant tell from the drawing in the manual. anyway something is broke or sticking in there and it looks like a chore to get to. tried to take the speed selector knob off by pulling out the set screw but the knob won't budge.don't want to break it by prying , that is were i a'm at present, i thought i'd ask you since you've already done this. the manual doesn't explain how the gear shift mechanism works so it's hard to figure out what might be broken . your help would be greatly appreciated. thanks pictures of the three cams, from left to right , with speed setting at 355 rpm

- Joined

- Apr 28, 2014

- Messages

- 3,590

Lordy, that looks like a diagram for the headstock of a lathe. And this is for a Drill Press?

- Joined

- May 7, 2014

- Messages

- 776

Yeah , with auto down feed. low/high fwd/rev, and spin wheel speed select. Geared head. Built like a tank!!!! Just needs a better way with the nylon pieces. if memory serves, around 5/16 OD and 3/4-1" long. I have the one I took out still. there are oil points at the very top. They note to OIL Lightly every use or something like that. Drips right down into this gear push rod assy. anyway..... onward. I love mine!!!

- Joined

- Jul 18, 2017

- Messages

- 69

I am working on a Rockwell EFI-2, I believe it's the same unit. Thank you SO MUCH for the manual. Could you provide the lengths of those plastic pins? I have the worn pieces, but don't know how you calculated the original lengths. Also, any interest in making a few of those plastic cams for a fella?

I bought mine for $6 at an auction, that's not a typo. It came with a tub of shafts, gears, bearings, pins and bolts. I am slowly figuring it all out. One of the selector rings? that contain three bearings and a pin which goes between two gears was in three pieces in a baggie. I finally figured out what that was and am now making a replacement. I'm hoping this is why it was disassembled.

I bought mine for $6 at an auction, that's not a typo. It came with a tub of shafts, gears, bearings, pins and bolts. I am slowly figuring it all out. One of the selector rings? that contain three bearings and a pin which goes between two gears was in three pieces in a baggie. I finally figured out what that was and am now making a replacement. I'm hoping this is why it was disassembled.

- Joined

- May 7, 2014

- Messages

- 776

Hey... sorry for the late reply. I have a Pic and I'll upload the 3D file in iges and stl here for ya. anyone w/ a 3d Printer can make ya one. My kid has all the printers at his place now and I know he's buried w/ school (final year! WHOOT!) . So... I tried to upload and it seems I'm not allowed. Everything issues an invalid file format. Send me a PM (if I can even get those still w/o payin') w/ an email and I'll send them along. maybe someone can post the 3D files up.. I get a ping about 1x or 2x a year on these it seems. Just over 18mm (18.03) but it's not the most accurate one. and you can see the wear groove in the bad one. 7.3mm OD x 18mm L For mine, the bad one was the one farthest from the front dial. PIA to take apart and get back, but it can be done. The other 2 are easily removed or replaced.