-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[Lathe] Does Anyone Have A Tiawanese Lathe Rml1440

- Thread starter malmac

- Start date

- Joined

- Apr 17, 2018

- Messages

- 536

- Joined

- Jun 7, 2016

- Messages

- 361

Well needed to cut some acme threads in square rod.....so mounted the four jaw chuck for the first time yesterday - glad I installed a small lifting device to take the chucks off the machine.... that worked fine.

Today needed to install different change gears to cut the specific thread pitch I needed - that worked out fine.

Cut two of the blocks - very happy with the controls on the machine.

Another two blocks will have their threads cut tomorrow.

In regards to accuracy, I am getting better but still not spot on every time and have not done any really critical work yet - but each time I use the lathe I try and cut to a specific size so I get better at working with the machine.

Very happy with the size of the machine - probably - definitely got carried away with the quality of machine - I could have done fine with a machine at around half the price.

I guess we all have our foibles.

Cheers Mal

Today needed to install different change gears to cut the specific thread pitch I needed - that worked out fine.

Cut two of the blocks - very happy with the controls on the machine.

Another two blocks will have their threads cut tomorrow.

In regards to accuracy, I am getting better but still not spot on every time and have not done any really critical work yet - but each time I use the lathe I try and cut to a specific size so I get better at working with the machine.

Very happy with the size of the machine - probably - definitely got carried away with the quality of machine - I could have done fine with a machine at around half the price.

I guess we all have our foibles.

Cheers Mal

- Joined

- May 16, 2016

- Messages

- 1,695

G'day Mal, Generally I stick to the concept of always buy the best you can afford, and within reason the biggest you have room for.

- Joined

- Jun 7, 2016

- Messages

- 361

G'day Mal, Generally I stick to the concept of always buy the best you can afford, and within reason the biggest you have room for.

Bob, I tend to behave that way as well - but sometimes my shed is not quite as big as I would like it and my budget is never as big as my aspirations. Oh well - it is a nice lathe to work with. I did look at the Liang Dei lathe which would have been quite enough for me but I just got carried away.

- Joined

- May 16, 2016

- Messages

- 1,695

My shed is just a small corner of the car garage, which is why I had to limit the length of my lathe to 16" between centers, I would love to have been able to go to 24" or wow 36". Then I could have had a gap bed, which would be great, but unfortunately NO room. And of course no room for a mill, again I would love to have one ideally a small bridgeport or clone thereof.

Having said that, I'm very happy with thE LD, the 12" swing is just enough and I'll probably never need a longer bed, I guess it's really the gap that I miss, although my lathe without the gap will be more rigid, so that will help with the milling that I intend to do on it. I have already done a bit and pleasantly surprised at what I can get away with.

I must put some pictures up soon of the vertical spindle attachment I'm building, and I will use the cross slide as the table.

Having said that, I'm very happy with thE LD, the 12" swing is just enough and I'll probably never need a longer bed, I guess it's really the gap that I miss, although my lathe without the gap will be more rigid, so that will help with the milling that I intend to do on it. I have already done a bit and pleasantly surprised at what I can get away with.

I must put some pictures up soon of the vertical spindle attachment I'm building, and I will use the cross slide as the table.

Last edited:

- Joined

- Jun 7, 2016

- Messages

- 361

I guess a question I would like to ask you is - what do you make, want to make using your lathe / mill combo.

As much as I would like to be restoring my old motorbike, I seem to spend all my time repairing and upgrading our slide on camper. I sometimes ask, will that ever end?

I was bit confused because the avatar pic you use does not look like your lathe - or am I mistaken?

Mal

As much as I would like to be restoring my old motorbike, I seem to spend all my time repairing and upgrading our slide on camper. I sometimes ask, will that ever end?

I was bit confused because the avatar pic you use does not look like your lathe - or am I mistaken?

Mal

- Joined

- May 16, 2016

- Messages

- 1,695

Mal, last question first. Yes that is my lathe, an actual photo of it when i first picked it up It is in my garage , but not fully positioned yet. In what way should it look different. As to what do I want to make. When I first decided to get a lathe about a year before the actual event. I just wanted to do some machining, I had not thought about making anything, just repairing stuff and maybe making a special; screw or shaft for a mate, or myself.

But when the lathe arrived my friends started asking what will I make, and made suggestions generally centered around various steam engines. I gave it some thought, and decided no, I would not make a steam engine, although certain historic ones might interest me, no.

As it happens, I'm something of a Harley Davidson fan, currently riding my 3rd HD. Then I thought what if I made a scale model 1/4 scale of a HD motor, one that actually runs with that classic beat.

that is when I realised I'm going to need to do some serious milling, so that's where I'm at.

But when the lathe arrived my friends started asking what will I make, and made suggestions generally centered around various steam engines. I gave it some thought, and decided no, I would not make a steam engine, although certain historic ones might interest me, no.

As it happens, I'm something of a Harley Davidson fan, currently riding my 3rd HD. Then I thought what if I made a scale model 1/4 scale of a HD motor, one that actually runs with that classic beat.

that is when I realised I'm going to need to do some serious milling, so that's where I'm at.

- Joined

- May 16, 2016

- Messages

- 1,695

I've decided to make my engine as near to 1/4 scale, as I can, of the 1340cc (80cu inch) EVO motor which was in production from 1988 to 2000. A fairly simple motor by modern standards I have started acquiring various second hand parts so that I can measure them and work out some 1/4 scale dimensions.

Last edited:

- Joined

- Dec 1, 2014

- Messages

- 56

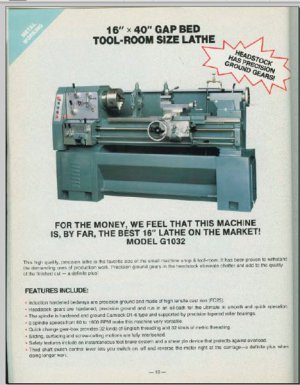

Well it sure is great to hear from Mal again about his baby. Lol I know I'm just like you both. I tend to go for the best tools I can afford. Being a carpenter by trade I have a garage full of wood working tools but the precision of metal working I think is where my heart is. I'd just love to see a few pics of Wally some day when you have a chance Mal. A dream machine like that sure sounds like a real treat to use. I'm just waiting and biding my time till I can afford a sweet machine like yours.