- Joined

- Jun 7, 2016

- Messages

- 361

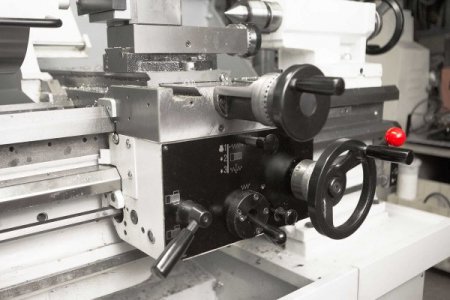

Mal, last question first. Yes that is my lathe, an actual photo of it when i first picked it up It is in my garage , but not fully positioned yet. In what way should it look different. As to what do I want to make. When I first decided to get a lathe about a year before the actual event. I just wanted to do some machining, I had not thought about making anything, just repairing stuff and maybe making a special; screw or shaft for a mate, or myself.

But when the lathe arrived my friends started asking what will I make, and made suggestions generally centered around various steam engines. I gave it some thought, and decided no, I would not make a steam engine, although certain historic ones might interest me, no.

As it happens, I'm something of a Harley Davidson fan, currently riding my 3rd HD. Then I thought what if I made a scale model 1/4 scale of a HD motor, one that actually runs with that classic beat.

that is when I realised I'm going to need to do some serious milling, so that's where I'm at.

Bob I looked up your Lathe and then I looked at your photo. Who ever took your photo has done a good job, because your lathe looks far more impressive than their sales brochure photo. To be honest, I really only need a lathe like yours, I just got carried away.

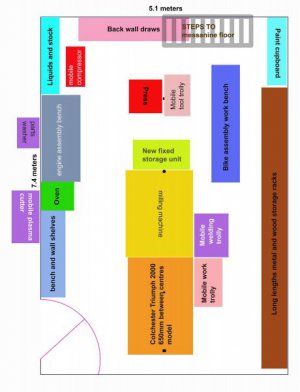

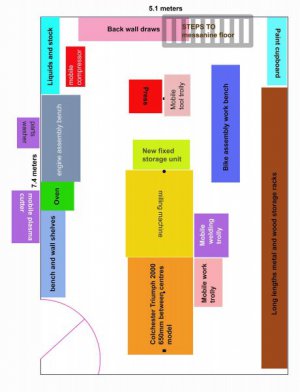

I am currently in the throws of replacing my shed compressor and trying really had not to get carried away. I have cleared a space (which is a bit hard to find) and working on what will fit.

The 1/4 scale running engine project is way beyond me but I know for sure, many of us here on the forum will be eager to hear of each small step you make towards realizing your dream.

Mal