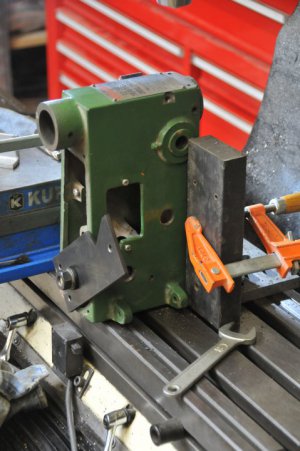

1982 Central Machinery (Harbor Frt.) drill press that I had bought new and used with contour sanding wheels. It ran too rough to now use for metal. I took it completely apart. New bearings, new quill depth stop, new quill lock, machined the table true, tapped some screws into the head to hold it better to the column. Assorted other minor tweaks. Cleaned, polished, painted, reassembled. Test drilled and not good. Put an indicator to a gage pin in the chuck, .009" runout! Took the chuck back off using my homemade wedges. Put an indicator on the tapered arbor and there was barely any movement of the needle. Conclusion, bad chuck. JT-3 taper. Looking for a decent one online. The last photo is the setup to mill a flat & tap holes for the quill depth stop.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drill press rehab

- Thread starter Larry$

- Start date

- Joined

- Dec 12, 2016

- Messages

- 495

Good work!

I have a Taiwanese Delta DP that I need to do a bearing overhaul on soon too...

I have a Taiwanese Delta DP that I need to do a bearing overhaul on soon too...

Last edited:

- Joined

- Dec 18, 2019

- Messages

- 6,447

Have a Delta DP with some complaining bearings and a lot of runout as well. Have to add it to the growing project list.Good work!

I have a Taiwanese Delta DP that I need to do a bearing overhaul on soon too...

I've got that exact same drill press, except mine has a taller column! I bought it new probably 35 years ago. Last year, I tore it down and relubed the bearings for the first time. I also trammed it as best as I could. It's not the most precise machine out there, but I've never had any problems with it. For most of it's existence, I've used it on wood and plastic. Now that I'm into machining, I probably should work on it and do something similar to what you have with yours.

- Joined

- Jun 22, 2016

- Messages

- 280

Mine isn't the most ridged contraption and it sure wasn't designed with the user in mind. It had a quill depth stop that was good for +- 1/4" that didn't work at all anymore, never did work well. So I added the one on the front that uses a 1/2"-20tpi rod so it will take standard Bridgeport quick adjust stops. I had bought one for my mill that works OK. I haven't found that model yet but there are others that are quicker to use but can't be adjusted to a fuzz. Dirt cheap, may settle for one of those for now. I added a quick handle that bears directly on the quill for a lock. It was an awkward setup for the casting on the mill. Holding castings always seems to be a problem because there are few flat spots. In this case I put a treaded rod through the column opening to a 90° plate on the mill and added some blocks to trap it from rotating. The fit of the quill in the casting is quite good, considering! The belt speed change on these things is a PIA. It has a 3/4 HP motor, sort of. Given the thin wire they used I seriously doubt the HP claim. I changed the location of the ground connection to a better bare metal location. I put the table on the lathe and took the dish shape out of it. There are Tee slots of sorts that don't fit any Tee nut well. Might look into changing that. At any rate for what it is, it will work.

Sounds like you made some great improvements! I agree about the POS depth stop. Mine is barely usable for wood level accuracy. I should follow your lead and fix that. The table bottom needs machining flat for any reliable t-nut holding. I have some t-nuts that fit the slots, but they rock back and forth in spots due to the rough finish on the table bottom. And yes, changing speeds is a PITA! I can drill using my mill, so improvements haven't been high on the priority list, but I'll probably get to them eventually unless I find a better drill press for a reasonable price. I would like one with continuously variable speeds and a bigger table. Like I said, though, this one does the job, despite its dubious parentage.

Me too, but sometimes I don't plan ahead and the mill has a setup I don't want to disturb.I can drill using my mill,

Me too. Seems like almost all the drill presses I see come up are POS Chinese junk. Different paint but same things.I would like one with continuously variable speeds and a bigger table