-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drilling insulated firebrick

- Thread starter jwmelvin

- Start date

- Joined

- Dec 9, 2016

- Messages

- 1,133

But I’m also working on a 3D printed core to burn out after casting refractory around it.

In the past ive used cheap crayons and candles sized as needed so that I could melt them out at a later point in the project like you are talking about with the 3d printed jig. Anyway a piece of styrofoam, a big box of crayons and a few pieces of wood and you have yourself very quick and easy and effective mold jig to cast the ribbon burner.

Yea, it seems like there are a variety of possible ways to do it. Here is a picture of the couple test holes I drilled in the firebrick:In the past ive used cheap crayons and candles sized as needed so that I could melt them out at a later point in the project like you are talking about with the 3d printed jig. Anyway a piece of styrofoam, a big box of crayons and a few pieces of wood and you have yourself very quick and easy and effective mold jig to cast the ribbon burner.

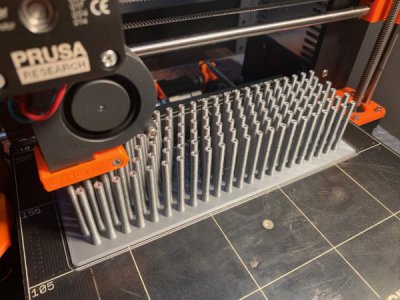

They were full depth of that bit, which I think would work but I'd have to resaw the firebrick down from 2.5" to maybe 1.5". Possible, but that's what led me to design this core for a molded nozzle (138 nozzles, 4 mm dia., 8"x2.5" opening):

I'm excited to get my castable refractory and see if I can make a nozzle.

That 3D print is awesome! That should work great! What refractory will you use?

Robert

Thanks, I’m looking forward to it. I ordered mystery refractory #2 from Wayne Coe Forge. I also have Kast-O-Lite 30.

- Joined

- Dec 9, 2016

- Messages

- 1,133

Do you plan on casting directly onto the metal part of the burner or do you have a different option for connecting the 2 pieces together?

Do you plan on casting directly onto the metal part of the burner...

That was my plan. Unless you suggest otherwise?

- Joined

- Dec 9, 2016

- Messages

- 1,133

Nope that's what i was going to suggest.

- Joined

- Mar 25, 2013

- Messages

- 4,614

Keep in mind that metal and ceramic have differing thermal expansion. You need some way to hold the ceramic that can account for this. If they are rigidly attached the metal will stretch the ceramic and crack it. Of course some cracking may be inevitable.

Robert

Robert