- Joined

- Mar 25, 2013

- Messages

- 4,638

I agree with Bob that the angles are not at all critical in that application. However, I am guessing those holes are angled in 2 planes? That would complicate it a little.

I am not trying to dissuade you from your project but might I point you in another direction? Here's what I use for my tungsten grinder.

($55) https://www.harborfreight.com/120-volt-circular-saw-blade-sharpener-96687.html

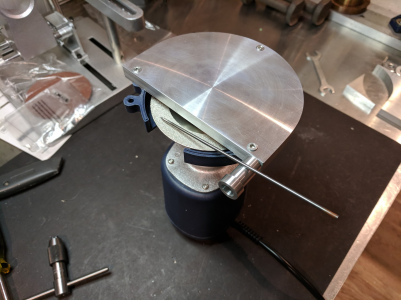

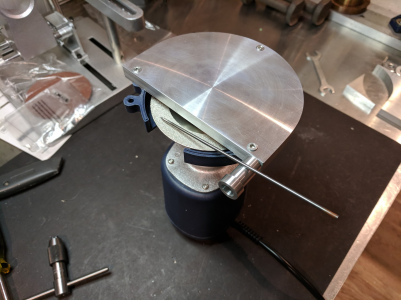

If you extract the motor and diamond wheel you get this:

I then made a simple cover and a guide. With the larger wheel this works amazingly well.

It is fairly compact and does not tie up my rotary tool. Please show us your work as you proceed on whichever path you choose.

Robert

I am not trying to dissuade you from your project but might I point you in another direction? Here's what I use for my tungsten grinder.

($55) https://www.harborfreight.com/120-volt-circular-saw-blade-sharpener-96687.html

If you extract the motor and diamond wheel you get this:

I then made a simple cover and a guide. With the larger wheel this works amazingly well.

It is fairly compact and does not tie up my rotary tool. Please show us your work as you proceed on whichever path you choose.

Robert