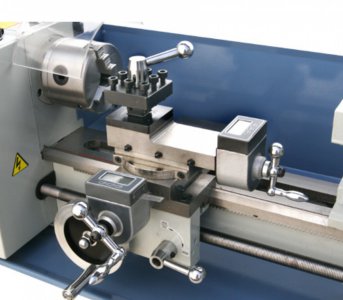

I installed an iGaging DRO on the Z axis of my 7x12. Due to some previous bad experiences with their aluminum scales, I went with their stainless steel scale. Still, I had a few EMI problems, solved by installing a 1 microfarad capacitor in the sensor (between its Vcc and Gnd). The controllers and continuously-variable RPM motors on this class of lathes seem to generate a lot of EMI that can mess with iGaging capacitive DROs, but if you've got even a little bit of soldering experience under your belt you can easily address the problem. At least, if you use a stainless steel rule. The aluminum ones develop contact problems and, based on my experience, require additional measures to get them to behave themselves.

That said, I now regularly use the DRO. The only downside is that it occasionally needs a new pair of 2032 batteries. I don't recall it EVER misbehaving after soldering in that additional capacitor.