- Joined

- Oct 4, 2011

- Messages

- 727

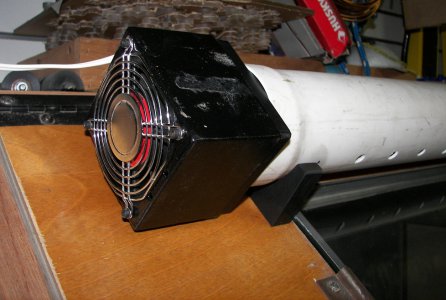

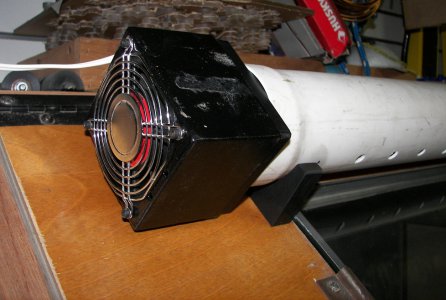

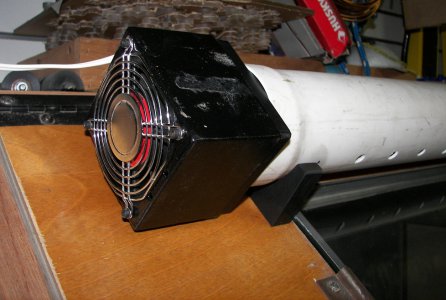

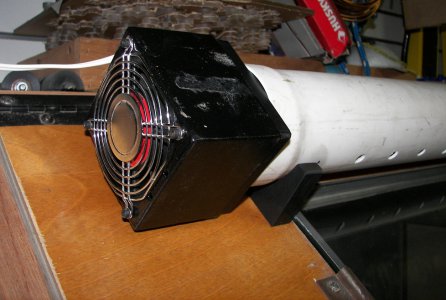

I did a tune-up of my sand blast cabinet this weekend. New glass, gun tip, grounding strap etc... One of the things that has always bugged me when using any sand blast cabinet is that the glass fogs on the outside from my breath. Maybe its just me. So I thought if I put a fan over the window it would keep it from fogging. :think1::think1: Since I can never do anything the simple way I decided a small 110v computer fan in a section of 3" PVC pipe would make a kind of air curtain across the window.

I wired it into the light for the cabinet so it comes on when the light does. It pivots on the mounting blocks so I can adjust the direction of the air. I used the cabinet for about 30 min straight with no fogging. :thumbsup: The entire project took about an hour to complete. I don't use the cabinet with a mask since I always run the vacuum with it and its sealed very well.

Jeff

I wired it into the light for the cabinet so it comes on when the light does. It pivots on the mounting blocks so I can adjust the direction of the air. I used the cabinet for about 30 min straight with no fogging. :thumbsup: The entire project took about an hour to complete. I don't use the cabinet with a mask since I always run the vacuum with it and its sealed very well.

Jeff