- Joined

- Oct 12, 2023

- Messages

- 29

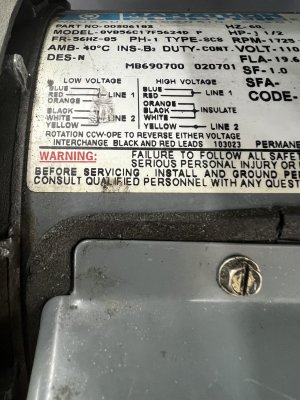

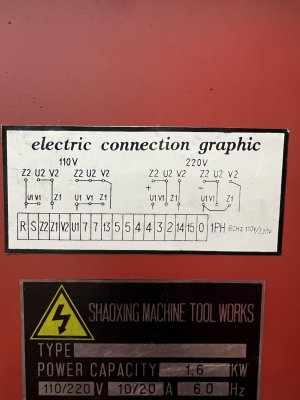

I just bought this lathe from a surplus store and in the process of restoring. I hooked up the motor to 220 and it runs. I mounted it to the lathe (no belts) and wired to the control panel. Using the photos I took before removing motor. I did not remove any other wiring/switches.

Applied power and the light illuminated. I hit start and the motor runs. I hit stop and it stops. Reset the stop button. The job/inch button does nothing. The apron switch (by the gear box) rotates and the motor lunges and now just smokes in two of the three positions. Up position motor runs.

I put 220 on the motor directly to ensure it still runs and it does. I noticed KM3 black button is depressed and will not “pop out”. Any advice would be greatly appreciated. I have attached pictures of wiring prior to removing motor, and control panel.

Applied power and the light illuminated. I hit start and the motor runs. I hit stop and it stops. Reset the stop button. The job/inch button does nothing. The apron switch (by the gear box) rotates and the motor lunges and now just smokes in two of the three positions. Up position motor runs.

I put 220 on the motor directly to ensure it still runs and it does. I noticed KM3 black button is depressed and will not “pop out”. Any advice would be greatly appreciated. I have attached pictures of wiring prior to removing motor, and control panel.