-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Enco Lathe 110-2079 Wiring Motor Issue

- Thread starter jmudler

- Start date

- Joined

- Oct 12, 2023

- Messages

- 29

Removed jumper wire from L2/L3 and powered breaker. Power light came on. Presses start with the forward/reverse lever in neutral position.

It breaker tripped and now KM1 little black button is depressed and will not reset.

It breaker tripped and now KM1 little black button is depressed and will not reset.

- Joined

- Apr 30, 2015

- Messages

- 11,302

OK you must have a shorted contactor on the output- Some more testing is in order

Do you have a multimeter? If so show me

Disconnect the motor and turn off the power and we can do some tests

Disconnect the 220 wire from the transformer and tape it

Give KM1 a few taps and see if you can free up the button- try it on KM3 also

Tap the button and the contactor itself- firmly but not so hard that it cracks the plastic

Do you have a multimeter? If so show me

Disconnect the motor and turn off the power and we can do some tests

Disconnect the 220 wire from the transformer and tape it

Give KM1 a few taps and see if you can free up the button- try it on KM3 also

Tap the button and the contactor itself- firmly but not so hard that it cracks the plastic

Last edited:

- Joined

- Oct 12, 2023

- Messages

- 29

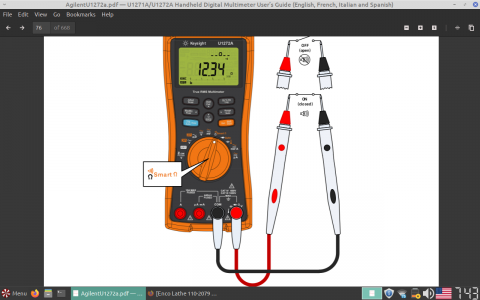

Yes I have a voltmeter it is a Agilent U1272A. I am away from the house till this afternoon and forgot to snap a picture. Below is a link. I tapped pretty hard on KM1 and KM3 and no reset

Thank you

Thank you

Last edited:

- Joined

- Apr 30, 2015

- Messages

- 11,302

- Joined

- Apr 30, 2015

- Messages

- 11,302

You'll probably want to download the actual user's guide for the meter- the file is too big for me to post it here

The link you posted is just a sales brochure

www.keysight.com

I would hold off on ordering any new contactors just yet until we diagnose what's wrong

www.keysight.com

I would hold off on ordering any new contactors just yet until we diagnose what's wrong

Also, shoot me another pic of the long terminal strip in the contactor box- straight on view so I can see it clearly-thx

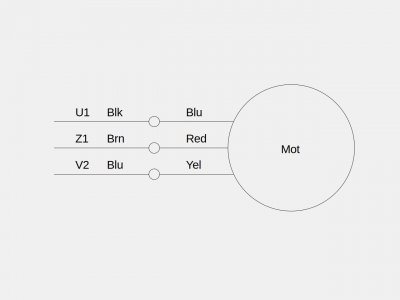

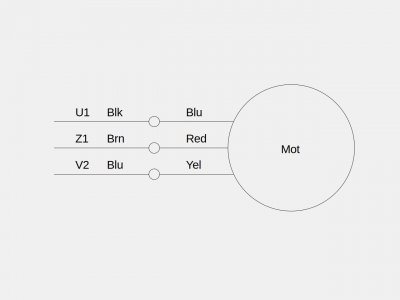

Is this drawing correct as far as the wire names?

The link you posted is just a sales brochure

U1271A/U1272A Handheld Digital Multimeter User’s Guide (English, French, Italian and Spanish)

This guide helps you get familiar with the U1271A/U1272A Handheld Digital Multimeter in English, French, Italian and Spanish. Always refer to the English version for the latest revision.

Also, shoot me another pic of the long terminal strip in the contactor box- straight on view so I can see it clearly-thx

Is this drawing correct as far as the wire names?

Last edited:

- Joined

- Oct 27, 2023

- Messages

- 330

Nice Lathe by the way. I have a 110-2031 which is supposed to be a gap bed however mine is not. Mine had been stripped of the wiring and replaced with an American motor and a vfd. Anyway I hope you get the bugs worked out of your new lathe

- Joined

- Apr 30, 2015

- Messages

- 11,302

This looks like a case of a contactor which is shorted internally- not a common problem but possible with

parts that have many operating hours on them

parts that have many operating hours on them

Last edited:

- Joined

- Apr 30, 2015

- Messages

- 11,302

When you get your meter ready to go, shut off the power and disconnect the motor and the 220 wire on the transformer.

Probe the three motor wires coming from the contactor box. Try all the combinations of wire pairs.

You should not hear a beep with any of the wire pairs.

If you do, either KM2 or KM3 may have an output short. Let me know what you find.

The contactor KM1 doesn't carry motor current, so if it's failing internally from old age I'm thinking you might need to replace all 3.

But don't run out and buy any just yet; don't remove them yet

Probe the three motor wires coming from the contactor box. Try all the combinations of wire pairs.

You should not hear a beep with any of the wire pairs.

If you do, either KM2 or KM3 may have an output short. Let me know what you find.

The contactor KM1 doesn't carry motor current, so if it's failing internally from old age I'm thinking you might need to replace all 3.

But don't run out and buy any just yet; don't remove them yet

Last edited:

- Joined

- Oct 12, 2023

- Messages

- 29

Thank you Pevehouse. I have a Allen Bradley VFD and motor sitting on the shelf for a milling machine down the road. I may end up using it on this. I wanted to learn with levels and dials.

P.S. My son attends AU by the way.

P.S. My son attends AU by the way.