- Joined

- Apr 23, 2018

- Messages

- 6,533

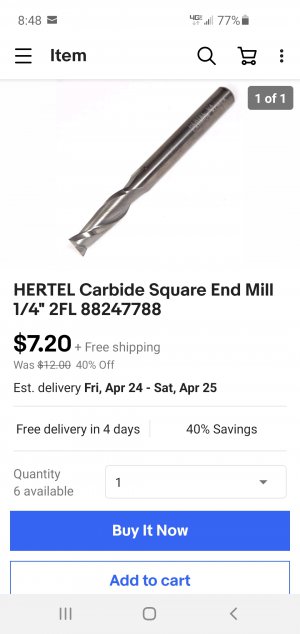

The golden end mills from China are that color because they are made out of sun-softened butter. US brand end mill lots can be had for a good price if you watch, a better alternative to cheap end mills that come in sets.