-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Evaporust ? Tell Me About It .

- Thread starter mmcmdl

- Start date

F

f350ca

Forum Guest

Register Today

Hi Stan,

Was a nice sunny day when I pulled the parts, I washed them with the pressure washer, any stubborn areas were rubbed with a scotch bright pad to remove the black oxide layer then blew the water off with an air hose and let them dry in the sun. I masked the bare parts for painting and oiled the rest with way oil being careful to not get it where I wanted to paint. Sprayed them right away. There was no rust under the tape when I stripped it.

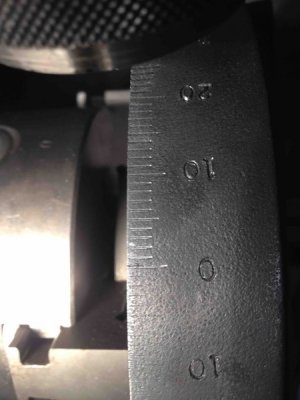

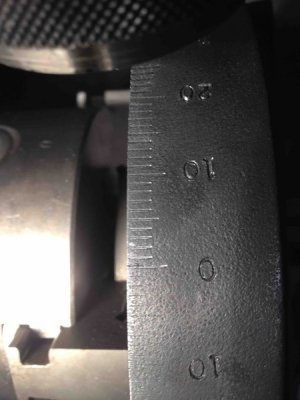

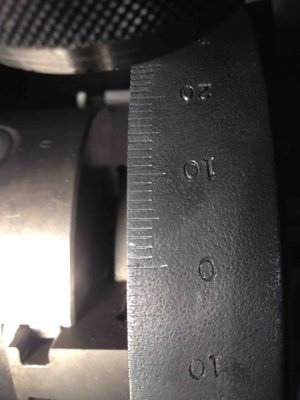

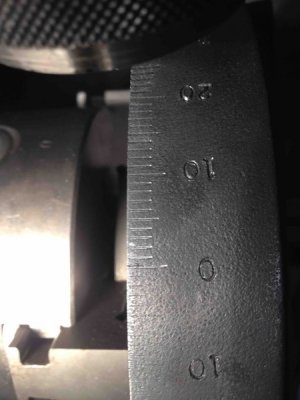

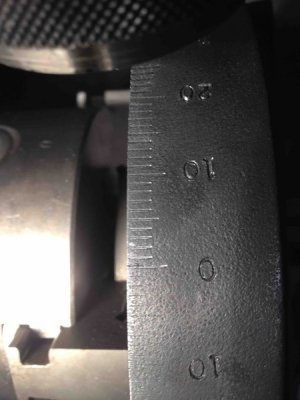

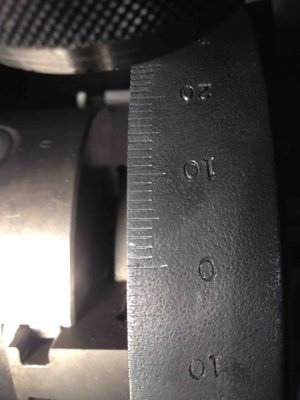

Depending on how much rust you have you may not get a perfect surface, This poor old girl was in rough shape. You can see the pitting here, and I had to recut the divisions and stamp the numbers to make them legible again. Was lucky though, the sliding surfaces were still covered in very dryed oil which protected them.

Greg

Was a nice sunny day when I pulled the parts, I washed them with the pressure washer, any stubborn areas were rubbed with a scotch bright pad to remove the black oxide layer then blew the water off with an air hose and let them dry in the sun. I masked the bare parts for painting and oiled the rest with way oil being careful to not get it where I wanted to paint. Sprayed them right away. There was no rust under the tape when I stripped it.

Depending on how much rust you have you may not get a perfect surface, This poor old girl was in rough shape. You can see the pitting here, and I had to recut the divisions and stamp the numbers to make them legible again. Was lucky though, the sliding surfaces were still covered in very dryed oil which protected them.

Greg

- Joined

- Jul 2, 2014

- Messages

- 7,594

Products that contain acid will definitely dissolve rust. They will also dissolve the underlying metal. If you have a nicely ground precision angle block with a bit of surface rust, Evaporust or electrolysis or molasses will dissolve the rust and the shiny finish will remain intact. If you use an acid based product, the surface will be etched after removing the rust. If it is something that will be painted, that is probably a plus. If it is a nice Hermann Schmidt toolmaker's vise, it will make you really unhappy. If it is an old and pitted hammer, it doesn't make much difference what you use. When the rust is removed, any pitting caused by the conversion of iron into rust will be visible in all its glory. None of the products mentioned on this thread will put good metal back where the rust has eaten it. An ounce of prevention is worth a pound of cure...

- Joined

- Jun 12, 2014

- Messages

- 401

I've trie electrolysis and it works. Evaporust was next on the list, until I saw about white vinegar, which I just tried.

Wow! Mr. Cheapo in me can't buy Evaporust when vinegar works so well. I have a few more things to derust, so we'll take some before/after pics.

Wow! Mr. Cheapo in me can't buy Evaporust when vinegar works so well. I have a few more things to derust, so we'll take some before/after pics.

I have used it for years. If you are in the midwest near a Rural King they sell it for about $16 a gallon.

I saw a demo on a car TV show recently (OK, most car shows are more like infomercials) were they used Evaporust on a large part (front subframe?) by setting it in something like a child's swimming pool and using a small pump to continuously recirculate the Evaporust back up to the top of the part. Sort of like a garden fountain. The part was always kept wet.

I saw a demo on a car TV show recently (OK, most car shows are more like infomercials) were they used Evaporust on a large part (front subframe?) by setting it in something like a child's swimming pool and using a small pump to continuously recirculate the Evaporust back up to the top of the part. Sort of like a garden fountain. The part was always kept wet.

- Joined

- Feb 27, 2012

- Messages

- 377

Greg,

Nice work on recutting the divisions and numbers. And thanks for the tips. Fortunately the rust on mine is not too bad. The small parts of it that I've done so far, I soaked in degreaser I got from Harbor Freight (purple stuff) that lifted the old paint, then in Evaporust. But I guess I didn't get back to it quick enough to paint/oil because I've got some flash rust to deal with.

Stan,

Sent from my iPhone using Tapatalk

Nice work on recutting the divisions and numbers. And thanks for the tips. Fortunately the rust on mine is not too bad. The small parts of it that I've done so far, I soaked in degreaser I got from Harbor Freight (purple stuff) that lifted the old paint, then in Evaporust. But I guess I didn't get back to it quick enough to paint/oil because I've got some flash rust to deal with.

Stan,

Sent from my iPhone using Tapatalk

- Joined

- Nov 12, 2015

- Messages

- 497

I was all excited about evaporust until I read mikegt4's post about having to keep it circulating to work. Yesterday I wire wheeled the rear end of my truck and it looked like I was in a dust storm. I'm so glad I had a respirator on, the filters are rust brown. I'm looking to make life easier in the way of removing the rust off the truck frame before paint, it's POR 15 but being how I am, I would like to get as much rust off before painting. Some pretty long runs of frame with rust and some areas I can't get wire wheels in to.

Does evaporust (and others) leave a surface coat that need to be removed before paint?

Does evaporust (and others) leave a surface coat that need to be removed before paint?

- Joined

- Jan 26, 2015

- Messages

- 1,939

I used Evaporust once, when I first heard about it. I was rebuilding old motorcycles at the time and it was great for removing rust on small parts. But the cost prohibited me from doing very large parts. I then looked into electrolysis. The cost was so minimal that I use that method now. I got a steel drum for free, bought a box of washing soda for $3. Mixed the soda with water in the drum. Had a couple car batteries that were still good. So hooked them up to the drum and part along with my battery charger and hung the parts in the drum and left them til next day. All the rust was gone. The electrolysis stops working all by itself. If you watch it, you will see it bubble. But as time goes by the bubbles slow down and eventually stop. But I did the parts for less than $5 instead of $30 - $40. The electrolite stays good and if water evaporates you add water and maybe some more washing soda. I also now have a 5 gal bucket with rebar mounted along the side for smaller parts.

- Joined

- Jul 2, 2014

- Messages

- 7,594

You do not need to circulate Evaporust for it to work. That discussion was about doing a large part and trying to keep the whole thing wet continuously when a submerged bath was out of the question. When Evaporust, or electrolysis, or molasses, or acids dissolve the rust the carbon that was previously in the steel will be left on the surface, and will need to be cleaned off if you do not like the black finish. It is easy to do with fine Scotchbrite. The more rust removed, the blacker the surface.I was all excited about evaporust until I read mikegt4's post about having to keep it circulating to work. Yesterday I wire wheeled the rear end of my truck and it looked like I was in a dust storm. I'm so glad I had a respirator on, the filters are rust brown. I'm looking to make life easier in the way of removing the rust off the truck frame before paint, it's POR 15 but being how I am, I would like to get as much rust off before painting. Some pretty long runs of frame with rust and some areas I can't get wire wheels in to.

Does evaporust (and others) leave a surface coat that need to be removed before paint?