@DeadGuyAle , the back plate was a solution borne of frustration. The 1-7/8"-8 spindle nose pitch as a standard is as dead as last week's cabbage, and plates and accessories for it are as unobtanium as any of the rest of the 10L/R parts. I occasionally see chucks with backing plates going for $500 on up, or dog plates, and CDCOTools.com has a 5C collet chuck with semi-finished backing plate in that pitch, but not with their 3-jaw, nor do they sell the backing plate by itself.

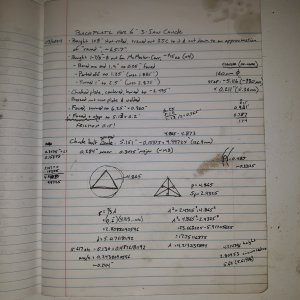

I am well aware that blank plates exist, as well as cast iron round slabs, but a) having no chuck at home, if I didn't have access to a lathe at work I couldn't thread it, and b) I've never threaded before, so I didn't want to spend $30-50 on a plate or slab and bugger it up. I found the nuts at McMaster through a random web search for that thread pitch, and concocted the solution over time. Originally I was just going to butt-weld the nuts to the plates, but worried that the torque (and overhang) would eventually cause it to fail, so I devised the bore and fit job. I could have done the nut work at home, but the breakage of the toolpost hamstrung me. At that point, I managed to secure approval to use the tooling at work, which helped a lot.

All this jiggery-pokery goes hand-in-hand with the lathe itself. It's as swaybacked as an old mare, possibly beyond recovery due to years or decades of neglect (look for my first post to see a pic of the , and may not even have enough extra material left to be able to be planed or ground back into shape. In keeping with my limited budget and the extremely low price I paid for the lathe, I'm keeping all my purchases to a minimum not only to keep it on the cheap, but to teach myself to be creative as well as frugal with my solutions.