- Joined

- Aug 6, 2015

- Messages

- 3,908

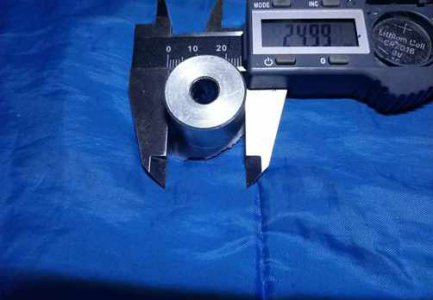

I was clueless... I ended up with several ER sizes simply due to ignorance... Had I known then what I know now, I would have done ER40 in all my machines... I think that I have ER20, ER32, and ER40I must admit, I had though about going for an ER40 system, but decided to stick to the ER32. For now......