- Joined

- Mar 28, 2023

- Messages

- 16

I have a Sherline lathe, but I recently ordered some accessories from Taig. I wanted their ER-16 collet adapter(1045ER), and to make shipping "worth it" I ordered their fly cutter(1224) and faceplate angle brackets(1036) just for fun. This is about the t-nuts that came with the faceplate angle brackets.

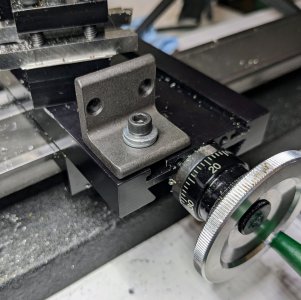

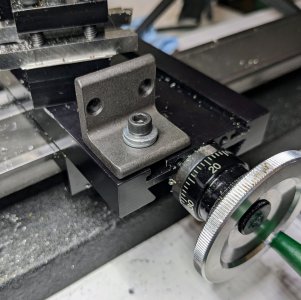

I went to test the angle brackets on my cross slide, and discovered the t-nuts are too thick to fit in Sherline's t-slots. I decided to see if I could remedy this. It seemed simple enough: turn them down a bit so that they're thin enough to fit, and in the process we get a small raised cylindrical section similar to how Sherline's t-nuts are. But how to mount them on the lathe? I ended up with this:

I took a scrap of aluminum, turned it, then drilled and tapped it for 10-32. I don't have a set of number drills, so I used a 4mm drill which was close enough to work in this case. I parted it off, turned it around, and dialed it in on the 4-jaw to face the other end. This one only my second time using the 4-jaw and it was great practice! I was able to get it fairly close--my indicator was wobbling a bit, but it was less than one thou and maybe less than a half. I then threaded a 10-32 screw from the back to the front, through the spindle bore. Now I was able to screw the t-nut on and tighten it with a wrench. This way the cutting forces should be tightening the nut:

I did measure the Sherline t-nuts, but mostly I just eyeballed it. I held a Sherline t-nut next to it to check thickness and screwed it on the front to check the diameter:

This is what the finished part looked like on the fixture:

and fitting into one of the t-slots on the cross slide:

One other thing I discovered is that the screws that came with brackets were a little too long for the Sherline t-slots. There are only two screws and t-nuts, though the brackets came with four washers. I'm not sure why they include four, but fortunately with two washers each, the screws did not bottom out in the slot:

I do not know what I'll use these for, but they were cheap and as I don't have a mill they may come in handy for simple parts holding if I need to run a cutting tool in the lathe spindle. A fun, small bit of problem solving if nothing else.

Cheers!

I went to test the angle brackets on my cross slide, and discovered the t-nuts are too thick to fit in Sherline's t-slots. I decided to see if I could remedy this. It seemed simple enough: turn them down a bit so that they're thin enough to fit, and in the process we get a small raised cylindrical section similar to how Sherline's t-nuts are. But how to mount them on the lathe? I ended up with this:

I took a scrap of aluminum, turned it, then drilled and tapped it for 10-32. I don't have a set of number drills, so I used a 4mm drill which was close enough to work in this case. I parted it off, turned it around, and dialed it in on the 4-jaw to face the other end. This one only my second time using the 4-jaw and it was great practice! I was able to get it fairly close--my indicator was wobbling a bit, but it was less than one thou and maybe less than a half. I then threaded a 10-32 screw from the back to the front, through the spindle bore. Now I was able to screw the t-nut on and tighten it with a wrench. This way the cutting forces should be tightening the nut:

I did measure the Sherline t-nuts, but mostly I just eyeballed it. I held a Sherline t-nut next to it to check thickness and screwed it on the front to check the diameter:

This is what the finished part looked like on the fixture:

and fitting into one of the t-slots on the cross slide:

One other thing I discovered is that the screws that came with brackets were a little too long for the Sherline t-slots. There are only two screws and t-nuts, though the brackets came with four washers. I'm not sure why they include four, but fortunately with two washers each, the screws did not bottom out in the slot:

I do not know what I'll use these for, but they were cheap and as I don't have a mill they may come in handy for simple parts holding if I need to run a cutting tool in the lathe spindle. A fun, small bit of problem solving if nothing else.

Cheers!

Last edited: