- Joined

- Mar 27, 2022

- Messages

- 425

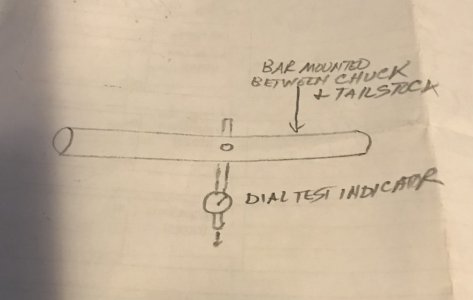

So I had been noticing that when setting tools to the tail stock they were miles from center at the headstock. Also the compound would get tight or loose when rotating.

I confirmed with a level that rotating the compound changes the pitch. Taking it apart I found that it’s been repaired. The repaired side is about .011” low.

What would be recommended for repair? I was thinking fly cut it down till flush and clean?

Would I indicate it in off the non damaged parts?

I confirmed with a level that rotating the compound changes the pitch. Taking it apart I found that it’s been repaired. The repaired side is about .011” low.

What would be recommended for repair? I was thinking fly cut it down till flush and clean?

Would I indicate it in off the non damaged parts?