- Joined

- Mar 26, 2018

- Messages

- 2,724

Hi All,

About 5 years ago I completed a CNC conversion of a Grizzly G0704 milling machine. Like everyone at that time I chose to go with the Hoss Machine style conversion as there were not many options on the market. I was not comfortable designing my own system at the time since I was just starting out in the hobby. The conversion was not glamorous, but it worked and I've tended to use the machine more than just fixing it up. The original purchase and conversion have been more than paid off in fun side jobs. I have literally thousands of great parts that have come off of this machine.

Fast forward to today, I am graduated from college and working for an industrial automation company (specifically in servomotor applications and control system design). I have been extremely fortunate to be able to get my hands on hardware leftover at work that I would have no justification to purchase on my own. Off and on over the last year I have been designing and building a complete system overhaul for the machine. I'm primarily focused on ease of use and reliability of the machine, but there should be huge performance increases as a result. I know everything you are about to see is complete overkill for this size machine, but I left it flexible enough to be transitioned onto a larger machine should I outgrow the G0704.

System overview:

The new control cabinet is a 24" x 36" x 8" sealed enclosure housing 6 AC servo drives.

Designed to be run from a Ethernet Smoothstepper and Mach 3/4, the Allen Bradley Ultra 3000 series drives power AB bulletin MPL servomotors.

The panel is wired for 40A @ 240VAC. It theoretically could pull 70A, but I don't foresee running all 6 drives at 100% at the same time. The control voltage is 24VDC which is coupled to the 5V Smoothstepper through optical isolators. All I/O points are broken out to M12 industrial connectors which include DC power and common to allow direct connection of 3 or 4 wire sensors. I have also purchased a pendant.

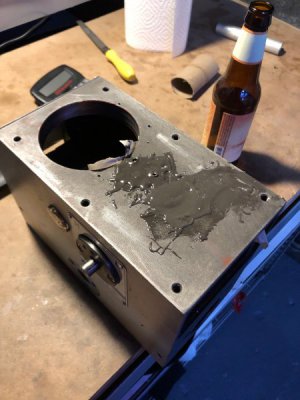

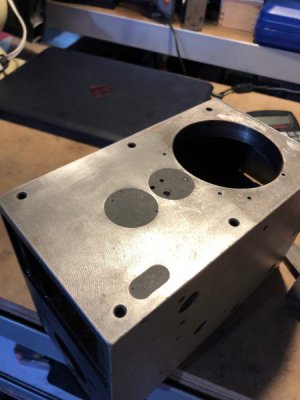

Mechanically, all of the original conversion hardware will be removed and replaced with new heavier duty components that are already built (not trying to make this a build log per se). The spindle is getting the most work as the bearings have been dying a slow death over the past year. The new design will be a totally sealed belt drive (noise reduction) and feature a pneumatic drawbar. I have started this process and will share lots of pictures in the next post.

Rebuild plans:

As promised by the title, some pictures:

The freshly completed Hoss Machine style conversion (ca 2012)

The very first control panel, literally just stepper drives and a power supply

Got a touch screen monitor

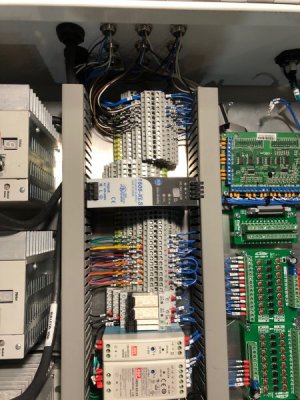

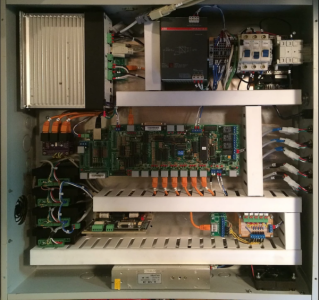

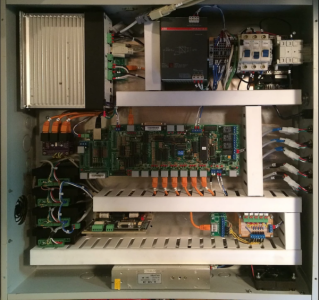

Upgraded control panel (ca 2013). Ethernet Smoothstepper, CNC4PC breakout boards, StepperOnline drives, and a DMM Tech DYN3 AC servo for the spindle.

As installed (24" x 24" x 6")

Servo spindle motor with belt drive and plastic cover

Pretty much what it looks like today, except for some cleaned up wiring.

Machining some valves for a robotic bartender I built with some buddies in college.

I hope you will follow along with me as I complete this project. I have been very grateful to this entire community for the knowledge that is shared, and I hope to be able to give back even if it is a fraction of what I have learned!

Mike

About 5 years ago I completed a CNC conversion of a Grizzly G0704 milling machine. Like everyone at that time I chose to go with the Hoss Machine style conversion as there were not many options on the market. I was not comfortable designing my own system at the time since I was just starting out in the hobby. The conversion was not glamorous, but it worked and I've tended to use the machine more than just fixing it up. The original purchase and conversion have been more than paid off in fun side jobs. I have literally thousands of great parts that have come off of this machine.

Fast forward to today, I am graduated from college and working for an industrial automation company (specifically in servomotor applications and control system design). I have been extremely fortunate to be able to get my hands on hardware leftover at work that I would have no justification to purchase on my own. Off and on over the last year I have been designing and building a complete system overhaul for the machine. I'm primarily focused on ease of use and reliability of the machine, but there should be huge performance increases as a result. I know everything you are about to see is complete overkill for this size machine, but I left it flexible enough to be transitioned onto a larger machine should I outgrow the G0704.

System overview:

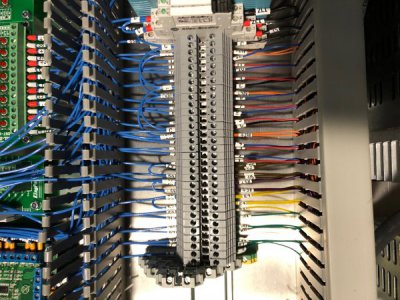

The new control cabinet is a 24" x 36" x 8" sealed enclosure housing 6 AC servo drives.

Designed to be run from a Ethernet Smoothstepper and Mach 3/4, the Allen Bradley Ultra 3000 series drives power AB bulletin MPL servomotors.

- X Axis - 0.75 kW 5000rpm Max, theoretical rapid 1000ipm, continuous thrust 350lbf, peak thrust 800lbf. High resolution multi-turn absolute encoder (~2M count/rev)

- Y Axis - 0.75 kW 5000rpm Max, theoretical rapid 1000ipm, continuous thrust 350lbf, peak thrust 800lbf. High resolution multi-turn absolute encoder (~2M count/rev)

- Z Axis - 1.80 kW 5000rpm Max, theoretical rapid 1000ipm, continuous thrust 900lbf, peak thrust 2400lbf. High resolution multi-turn absolute encoder (~2M count/rev)

- Spindle - 1.80kW 5000rpm Max, Continuous torque 4.18Nm, Peak torque 11.1 Nm, 1:1 gearing, High resolution single turn absolute encoder (~2M count/rev)

- 4th Axis - Prewired for up to 1kW. I have a high torque Alpha Wittenstein SP series gearbox which I plan to make a 4th axis with in the near future.

- 5th Axis / Spare - Prewired for up to 1kW.

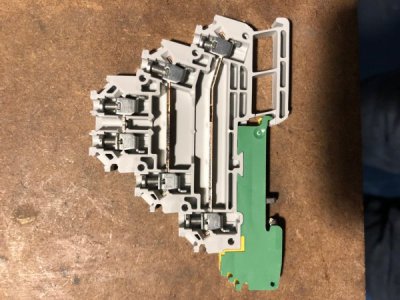

The panel is wired for 40A @ 240VAC. It theoretically could pull 70A, but I don't foresee running all 6 drives at 100% at the same time. The control voltage is 24VDC which is coupled to the 5V Smoothstepper through optical isolators. All I/O points are broken out to M12 industrial connectors which include DC power and common to allow direct connection of 3 or 4 wire sensors. I have also purchased a pendant.

Mechanically, all of the original conversion hardware will be removed and replaced with new heavier duty components that are already built (not trying to make this a build log per se). The spindle is getting the most work as the bearings have been dying a slow death over the past year. The new design will be a totally sealed belt drive (noise reduction) and feature a pneumatic drawbar. I have started this process and will share lots of pictures in the next post.

Rebuild plans:

- Rebuild spindle

- Install spindle motor, belt drive, and drawbar

- Remove old CNC components

- Install axis motors and mounts

- Install electrical cabinet

- Install limit/home switches

- Install wireway and cable routing

- Install touchscreen computer

- Migrate to Mach 4

- Validate system functionality

- Performance characterization

- Mach 4 Pendant Configuration

- Mach 4 LUA Scripting for servo drive serial communication (Diagnostics, true rigid tapping, absolute homing, gear hobbing, etc.)

As promised by the title, some pictures:

The freshly completed Hoss Machine style conversion (ca 2012)

The very first control panel, literally just stepper drives and a power supply

Got a touch screen monitor

Upgraded control panel (ca 2013). Ethernet Smoothstepper, CNC4PC breakout boards, StepperOnline drives, and a DMM Tech DYN3 AC servo for the spindle.

As installed (24" x 24" x 6")

Servo spindle motor with belt drive and plastic cover

Pretty much what it looks like today, except for some cleaned up wiring.

Machining some valves for a robotic bartender I built with some buddies in college.

I hope you will follow along with me as I complete this project. I have been very grateful to this entire community for the knowledge that is shared, and I hope to be able to give back even if it is a fraction of what I have learned!

Mike

Last edited: