-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G4000 lathe, like VFD motor upgrade , Help

- Thread starter Darryl

- Start date

- Joined

- Feb 2, 2013

- Messages

- 3,627

Hi Darryl,

You are going to need a 110 single phase input to 220v(nominal) 3 phase output VFD, a 1hp ,1750rpm (nominal) , 3 phase 220v motor .

The VFD is hooked up directly to the motor.

Provisions can be made to use the factory controls to operate the VFD’s DCM circuit.

Programming the VFD most likely will be necessary for optimal performance.

You are going to need a 110 single phase input to 220v(nominal) 3 phase output VFD, a 1hp ,1750rpm (nominal) , 3 phase 220v motor .

The VFD is hooked up directly to the motor.

Provisions can be made to use the factory controls to operate the VFD’s DCM circuit.

Programming the VFD most likely will be necessary for optimal performance.

thank you Doc, so your sayin the VFD 110v will put out 3 phase 220v to motor? I hope I understand, lolHi Darryl,

You are going to need a 110 single phase input to 220v(nominal) 3 phase output VFD, a 1hp ,1750rpm (nominal) , 3 phase 220v motor .

The VFD is hooked up directly to the motor.

Provisions can be made to use the factory controls to operate the VFD’s DCM circuit.

Programming the VFD most likely will be necessary for optimal performance.

- Joined

- Feb 2, 2013

- Messages

- 3,627

Yes sir, you got itthank you Doc, so your sayin the VFD 110v will put out 3 phase 220v to motor? I hope I understand, lol

- Joined

- Feb 2, 2013

- Messages

- 3,627

Here is a sample ( but not the only choice)

750W 220V Single to 3 Phase Frequency Converter Output Variable Converter VFD | eBay

1 X Single Phase Frequency Converter. This Product Has the General Basic Function of Frequency Converter. Max Input Currebt:0.65a,1.36a,2.34a,3.86a. Your satis faction is our ultimate goal.

www.ebay.com

thank you so muchHere is a sample ( but not the only choice)

750W 220V Single to 3 Phase Frequency Converter Output Variable Converter VFD | eBay

1 X Single Phase Frequency Converter. This Product Has the General Basic Function of Frequency Converter. Max Input Currebt:0.65a,1.36a,2.34a,3.86a. Your satis faction is our ultimate goal.www.ebay.com

thank you for your helpI did this to a 10 hp 3 phase. works great. Only draws 9 amps on start up, no blowing your house fuse. I recommend you buy from a local electric motor control dealer, that has a on site tech you can call or email for set up help.

Using the factory selector switch for forward and reverse is the easiest way to get running quickly, but you might want to install something like push buttons to start and stop the motor instead of using the factory switch. If you had a power failure, or tripped the vfd, it will start running again when power is restored if the run switch is left in the forward or reverse position. With push buttons, you can program it for three wire control so that if power is interrupted, you need to press start again to get the machine running instead of it running on its own. I had the Jet version of that lathe and the selector switch always made me nervous that I would forget to turn it off during a power failure or if I tripped a breaker, so since you are installing a VFD, that is a great time to eliminate that possibility. I did that for my mill that had a direction switch like your lathe has.

Another thing that would be useful is an emergency stop, lathes can be dangerous, so having a button you can hit quickly to immediately stop operation is highly recommended. That can be wired directly into the vfd so that it won’t run unless it sees the proper signal. The manual of your vfd should have info on how to wire that and program the vfd.

Some VFDs have removable control keypads, so you could install that on your machine and operate it that way, you would need to run the appropriate cable back to the VFD. That would give you control you will want without having to build a pushbutton panel.

Another thing that would be useful is an emergency stop, lathes can be dangerous, so having a button you can hit quickly to immediately stop operation is highly recommended. That can be wired directly into the vfd so that it won’t run unless it sees the proper signal. The manual of your vfd should have info on how to wire that and program the vfd.

Some VFDs have removable control keypads, so you could install that on your machine and operate it that way, you would need to run the appropriate cable back to the VFD. That would give you control you will want without having to build a pushbutton panel.

thanks , did you use the stock motor when you wired your VFD up? the lathe has the capacitors in the lathe ,not on the motor like most are.Using the factory selector switch for forward and reverse is the easiest way to get running quickly, but you might want to install something like push buttons to start and stop the motor instead of using the factory switch. If you had a power failure, or tripped the vfd, it will start running again when power is restored if the run switch is left in the forward or reverse position. With push buttons, you can program it for three wire control so that if power is interrupted, you need to press start again to get the machine running instead of it running on its own. I had the Jet version of that lathe and the selector switch always made me nervous that I would forget to turn it off during a power failure or if I tripped a breaker, so since you are installing a VFD, that is a great time to eliminate that possibility. I did that for my mill that had a direction switch like your lathe has.

Another thing that would be useful is an emergency stop, lathes can be dangerous, so having a button you can hit quickly to immediately stop operation is highly recommended. That can be wired directly into the vfd so that it won’t run unless it sees the proper signal. The manual of your vfd should have info on how to wire that and program the vfd.

Some VFDs have removable control keypads, so you could install that on your machine and operate it that way, you would need to run the appropriate cable back to the VFD. That would give you control you will want without having to build a pushbutton panel.

looking at the wiring PDF , I think I need to fined away to wire it , I too don't like that the lathe has no E-stop on it. my g0704 has it ..

I never put a VFD on my 9x20, it was single phase. I have a 12x36 lathe now that I added a VFD on it.

With your lathe, you need to replace the single phase motor with a three phase motor to use a standard VFD. There are single phase output VFDs, I have never used one, so can’t comment on if they are any good or not, but this company could be an option if the motor on your lathe is compatible.

http://www.gohz.com/single-phase-output-vfd

If you decide to go with a three phase motor, the first thing you need to check is the frame size of your current motor, it is likely metric. A NEMA motor that is most common here might not fit without modifications. One thing in particular is the shaft size, the pulley on the motor might need to be modified to fit a new motor.

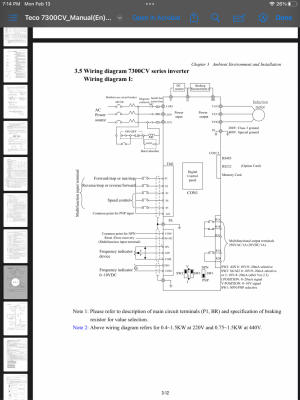

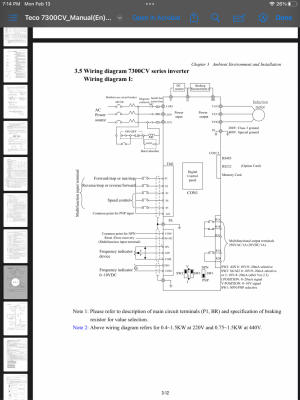

Whichever VFD you get, the VFD motor outputs get wired directly to the motor, and whichever switches you use to control the operation are wired to the VFD inputs. So, if you use the existing fwd/rev switch on your lathe, that would get rewired to the inputs on the VFD. Following is a schematic for my lathe VFD, yours might be different, but the left side is your inputs, and the right side shows the motor connected directly to the VFD. If you wanted to use push buttons with three wire control, the manual shows that in a later section, what is shown here is switches that stay closed like with the existing switch on your lathe.

With your lathe, you need to replace the single phase motor with a three phase motor to use a standard VFD. There are single phase output VFDs, I have never used one, so can’t comment on if they are any good or not, but this company could be an option if the motor on your lathe is compatible.

http://www.gohz.com/single-phase-output-vfd

If you decide to go with a three phase motor, the first thing you need to check is the frame size of your current motor, it is likely metric. A NEMA motor that is most common here might not fit without modifications. One thing in particular is the shaft size, the pulley on the motor might need to be modified to fit a new motor.

Whichever VFD you get, the VFD motor outputs get wired directly to the motor, and whichever switches you use to control the operation are wired to the VFD inputs. So, if you use the existing fwd/rev switch on your lathe, that would get rewired to the inputs on the VFD. Following is a schematic for my lathe VFD, yours might be different, but the left side is your inputs, and the right side shows the motor connected directly to the VFD. If you wanted to use push buttons with three wire control, the manual shows that in a later section, what is shown here is switches that stay closed like with the existing switch on your lathe.