- Joined

- Oct 4, 2020

- Messages

- 484

Planning on ordering a 1440GT Lathe.

I will get the 3 phase version. Slow spindle speed will be important to me at some point (chambering barrels)

I've been through this thread and read the diagrams in the thread titled "The Pm-1440gt Has Landed" by @jbolt (new account, so I cant share the link)

I've also seen and fully understand Clough42's 7 part series on converting his lathe to run on a 3 phase motor with a VFD. (hnew account, so I cant share the link)

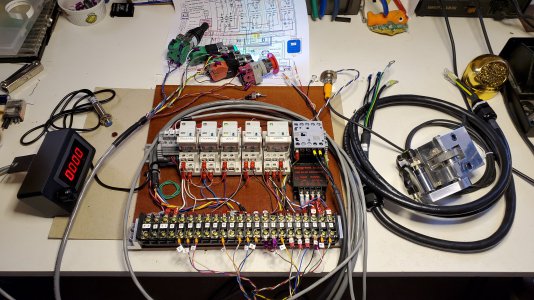

I'm comfortable with electronics, but everything that @mksj has in his wiring diagrams is a little overwhelming, especially without having the actual lathe to look at in person.

So, a couple questions.

* It seems like the Hitachi WJ200 is the VFD that is preferred. There are several sub-versions of it available... which one do I want?

* To get the lathe running, I don't need all of the extra things that mksj has done, correct? VFD with the basic lathe controls wired through it (direction, speed, stop) is all that would be required, correct?

I will get the 3 phase version. Slow spindle speed will be important to me at some point (chambering barrels)

I've been through this thread and read the diagrams in the thread titled "The Pm-1440gt Has Landed" by @jbolt (new account, so I cant share the link)

I've also seen and fully understand Clough42's 7 part series on converting his lathe to run on a 3 phase motor with a VFD. (hnew account, so I cant share the link)

I'm comfortable with electronics, but everything that @mksj has in his wiring diagrams is a little overwhelming, especially without having the actual lathe to look at in person.

So, a couple questions.

* It seems like the Hitachi WJ200 is the VFD that is preferred. There are several sub-versions of it available... which one do I want?

* To get the lathe running, I don't need all of the extra things that mksj has done, correct? VFD with the basic lathe controls wired through it (direction, speed, stop) is all that would be required, correct?