-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Getting rid of the compound slide?

- Thread starter Pcmaker

- Start date

All that needs to be done to keep track of movements is put a mag base dial indicator on your saddle and zero it out on a hard stop. Then you can move precisely.For me facing is one operation that is difficult to do without a compound slide.

Usually with the compound on,I let the tip of the cutting tool touch the face,(with the lathe off), lock the carriage ,move the compound back a couple of thou, turn the lathe on, move the compound forward a few thou , cut with the cross slide until done,but now without it I would have to move the carriage a couple of thou and that's not an easy task on a mini lathe.

- Joined

- May 31, 2018

- Messages

- 184

There are a number of other mods that people have done to their mini lathes to improve rigidity without losing any function. I fitted angular contact bearings to the spindle and this made a big difference. In an effort to get my mini lathe up and running again last night I re-adjusted these and have noticed a big improvement in the surface finish when facing.

Tapered gibs is another mod I know a lot of people have done. I would love to do it myself but I don't have a mill to make them so it's on the back burner for now.

When parting I have found it best to lock the carriage and compound if possible to prevent any movement. The biggest issue I have is the tool digging in and either snapping the parting blade or stalling the lathe. I personally found running at slightly higher speeds helped as the lathe had less of a tendency to stall. Keep the parting blade sharp too - if you try and push a blunt tool into the workpiece then that's a recipe for disaster.

Tapered gibs is another mod I know a lot of people have done. I would love to do it myself but I don't have a mill to make them so it's on the back burner for now.

When parting I have found it best to lock the carriage and compound if possible to prevent any movement. The biggest issue I have is the tool digging in and either snapping the parting blade or stalling the lathe. I personally found running at slightly higher speeds helped as the lathe had less of a tendency to stall. Keep the parting blade sharp too - if you try and push a blunt tool into the workpiece then that's a recipe for disaster.

- Joined

- Nov 17, 2017

- Messages

- 1,525

What size lathe is considered ridgid enough to part off as well as some other procedures? I was thinking of getting an 11 x 27 Precision Matthews lathe sometime in the future

I have never had any problems parting off with my G4003G 12*36 Even big hunks of steel.

- Joined

- Dec 26, 2016

- Messages

- 2,023

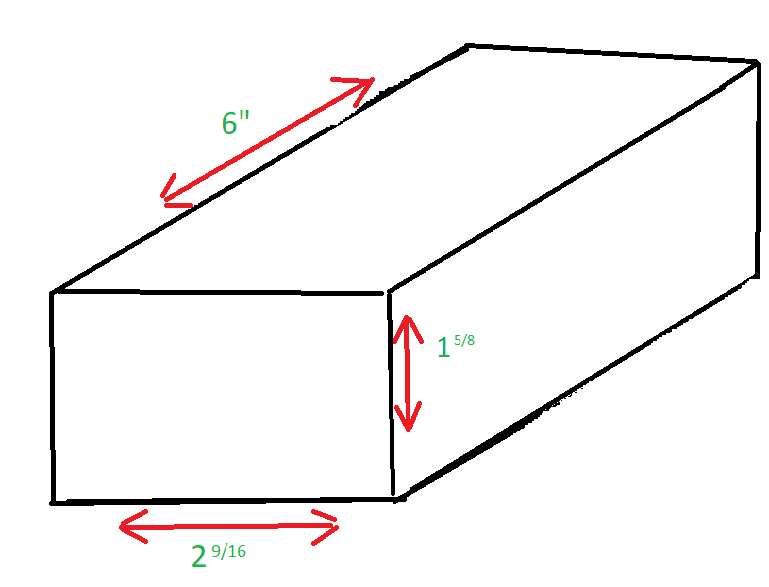

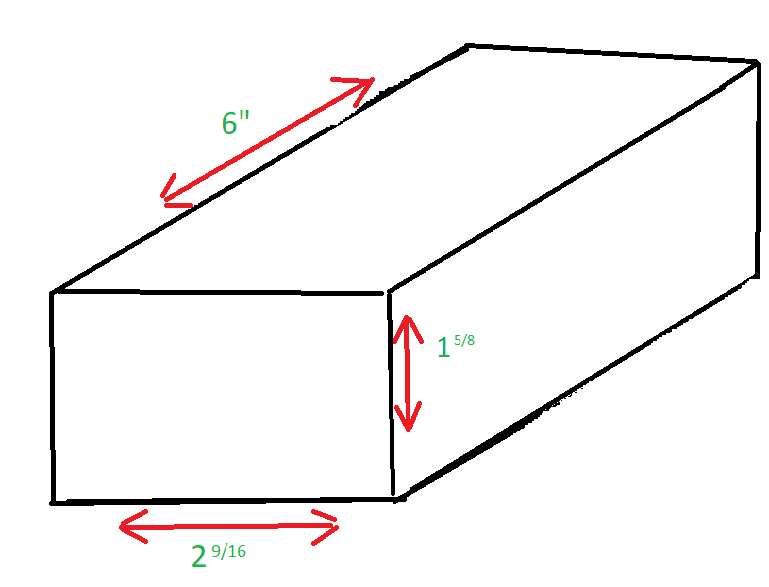

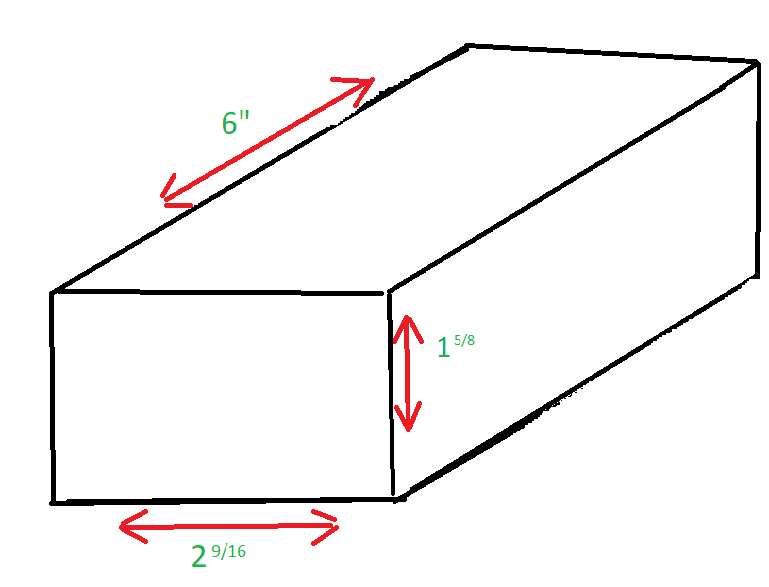

That doesn't sound right, 1.625" thick is what I'm thinking.

- Joined

- Jun 12, 2018

- Messages

- 712

Yeah, I just measured it and these are the dimensions of what I need. Anyone know where's a good place to get it online? Something exact or close enough and I can mill out the rest. I don't think it has to be exactly the same length and width as the block below it.

- Joined

- May 8, 2018

- Messages

- 336

Yeah, I just measured it and these are the dimensions of what I need. Anyone know where's a good place to get it online? Something exact or close enough and I can mill out the rest. I don't think it has to be exactly the same length and width as the block below it.

https://www.ebay.com/itm/THICK-Stee...:USPSPriorityMailSmallFlatRateBox!72764!US!-1