- Joined

- Sep 2, 2013

- Messages

- 378

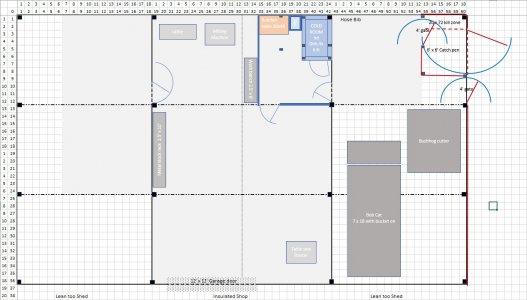

I built a 40X60 X12. This is my third and final try at shop building. I am very happy with it so far. In the front 2/3's I have the machining on one side and the opposite side is the welding, CNC and grinding. Forty foot apart I don't have any issues so far. A big door is in the center of this 40' and it leaves me plenty of room to bring in truck/tractor/project in the center. The back 1/3 is tractor and misc storage.