- Joined

- Nov 25, 2015

- Messages

- 8,382

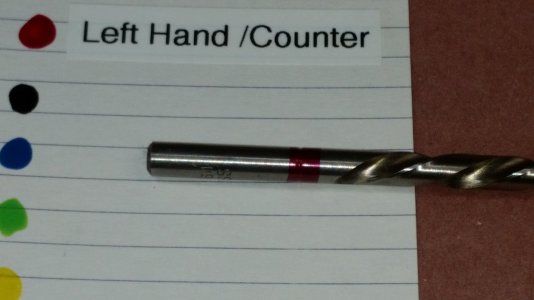

I had to mark my end mills first. I have a few counterclock wise end mills.. And I would always burn them up trying to cut clockwise.

After a few of those, I painted them red with dykem... but dykem comes off, so I started using the Testors model stuff. but again, no brush, so you had to clean a brush after... I could also use a dremel and put a slight groove around the body on the millls, and the nail polish would just hang in the groove.

After a few of those, I painted them red with dykem... but dykem comes off, so I started using the Testors model stuff. but again, no brush, so you had to clean a brush after... I could also use a dremel and put a slight groove around the body on the millls, and the nail polish would just hang in the groove.

I thought about going with a french manicure but figured that would've been a bit too hoity toity.

I thought about going with a french manicure but figured that would've been a bit too hoity toity.