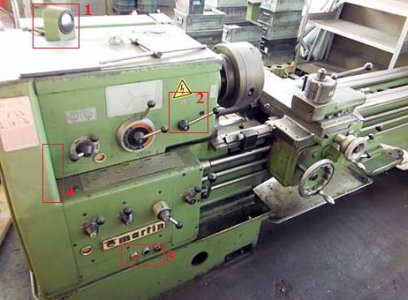

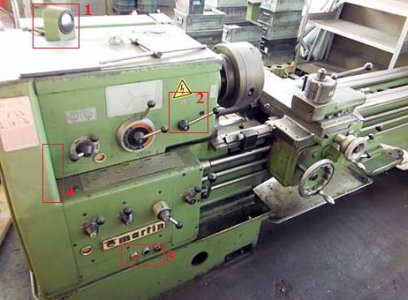

Onward to the electrical: I've been doing some more research, and I've found a few pictures of a '69 DLZ 503 for comparison because it's so favorably in many respects. There are differences. Let me post a few pictures for discussion. These are snagged from a site called "exapro.com" which I take it is a listing site dealing in used machinery. Again, this is a '69 DLZ 503:

On the front, I notice the item up top(Box 1)... What is that. Looks like a gauge of some sort. Box 2, I point only only to contrast to the machine I purchase, where the red and black dots indicating the ranges are situated more like a "V" with respect to the shifter fulcrum. This one, it forms a right-leaned "V". Interesting difference, but I'm sure insignificant. In Box 3, you see here two buttons and an indicator lamp, I suppose to tell you the machine is on. On and off switches to its left. On mine, there are two additional switches to the left of these three items, one for "Lamp" and one for "Coolant Pump", using iconography of a lightbulb and a faucet, respectively. Lastly, one of the subtler differences is this sheet metal that covers the belts et al on the end of the machine. If you look at box 4, you'll see the sheet metal is smoothly rolled over the corner on that slope. On mine, it's a hard corner.

Now, where it gets interesting:

Box number 1 is a cover that is present on mine, and seems to cover the end of a splined shaft that 4GSR has speculated is some sort of accessory drive. Interestingly, this seems to be (one of)the thing(s) that makes the difference between a 502 and a 503. When I look at pictures of the respective models on Google, those with this cover are all 503s and those without are 502s. Box number 2 is completely absent on my machine, and I suspect that's where all my missing electrical pieces would go. That's a guess. Seems reasonable. Maybe they took it off to look at the motor, or maybe it got damaged somewhere, or who knows, but it certainly isn't present on the machine I inspected Saturday. Box number 3 is a cover, and what it covers is this: (on mine, and I suspect on this one from exapro.com as well):

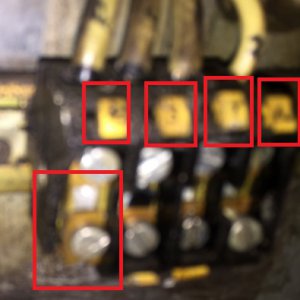

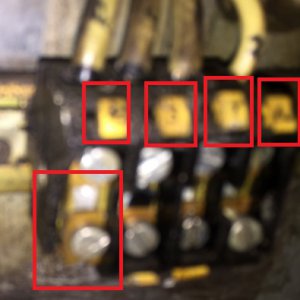

(I must have smudged the camera lens on my phone, because from about four pictures before this, every one after is cloudy/murky like this...I blame grease and grime.)

The four red boxes in a row at the top are labeled R S T N. I expect those are the three phase wires, plus neutral. Just out of frame here, is a ground wire that comes from the same bundle and bolts to the chassis directly to this component's right. The box to the lower left is to show that a chunk of the plastic of the component's housing is knocked off, broken, and probably has been that way for some time.

Lastly, this is the data plate on the motor on mine:

I can tell this is almost certainly the original motor because the use of commas in place of decimal points is a German thing. This is one time when being married to a native of Bavaria comes in handy. So 220/440v, 38.76/19.38 amps, 60HZ, 1750 RPM, and what the rest means, I have only guesses. If I had to tell you the physical frame, I'd guess it's very similar to 254T, based on the spread of the mounts and the size of the shaft(though I didn't measure the latter.)

Now my speculation would be that this lathe was probably taken out of service whenever that box disappeared. If the box was removed to access the motor, which is missing its electrical cover plate, then there's a pretty good chance the motor is toast. To remove the motor, you'd almost certainly have to remove that electrical box. Heck, to see the data plate pictured above, you'd have a hard time with that box in place over the motor.

So, for all you experienced hands, what can you discern from all of this?

Thanks!

Mark