That's fairly new modern wiring per the DIN specifications. It's readily available. Nothing special there. I say that.... I wouldn't tear any of it out just yet! Changing the voltages out to 240 volt, may require a larger starter if the existing one is not big enough to handle 15 HP on 240 volt. If it is big enough, just have to change out the heaters to the starter/contactor, if it has heaters. Europeans use some strange stuff for heaters. Those things in the upper top left of the picture, may be them, I don't know. If you decide to put different stuff in, give me a holler, I may have something here that will work.

Ken

Ken,

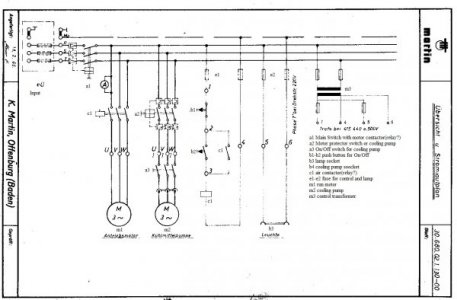

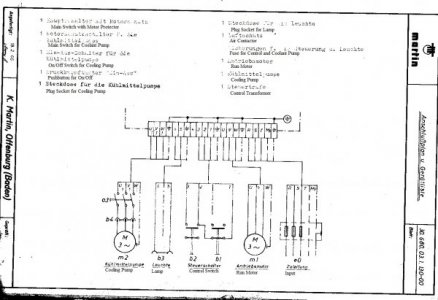

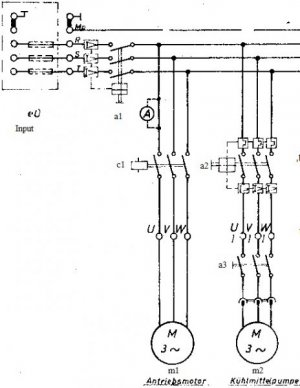

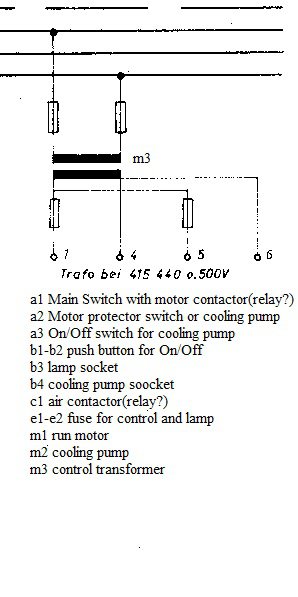

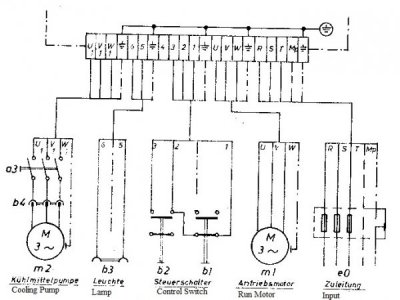

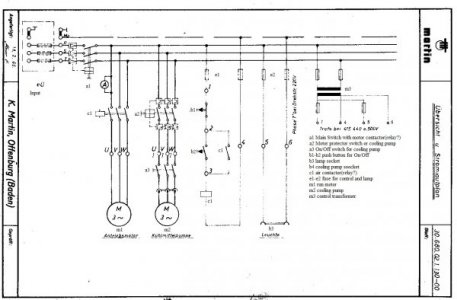

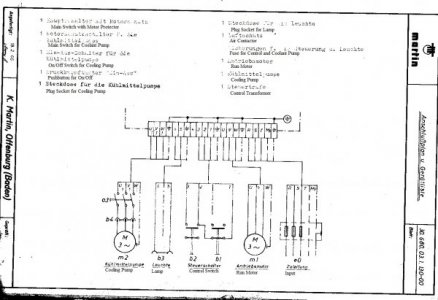

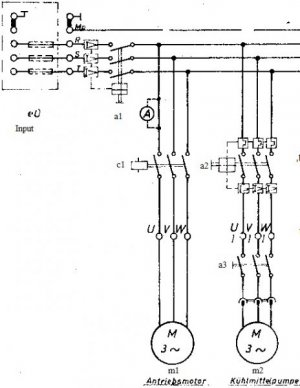

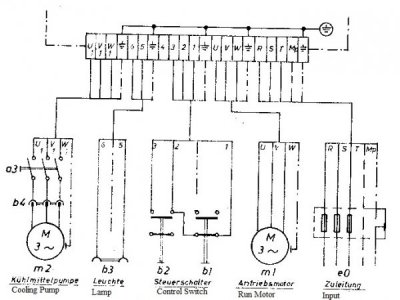

I'm going to have to build it all from scratch. As far as I can tell, the only electrics on the lathe, anywhere, are the motor, the start and stop switch on the front, two broken switches that should be the lamp and the coolant pump, the oddball piece at the bottom of the headstock pedestal pictured above(the fuzzy picture). That's what I'm saying. The rest is absent. So I'm going to need to effectively build the whole electrical system. The only wiring on the lathe seems to be the cut off wires coming from the switch panel, and the cut off wires coming from the cooling pump socket on the back of the middle pedestal. So basically, I'm starting from scratch. I'm willing to assume that every electrical piece on the machine is bad, since there are few anyway. The only thing I hold out any hope of being okay is the motor, and that's a slim hope.

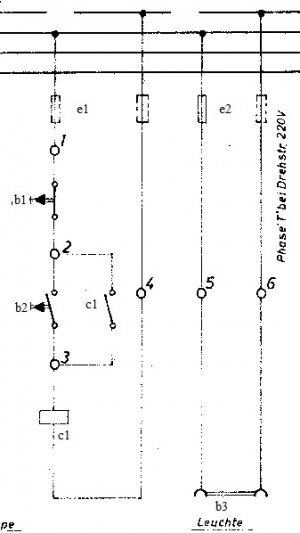

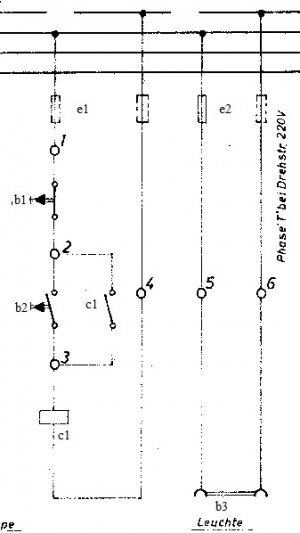

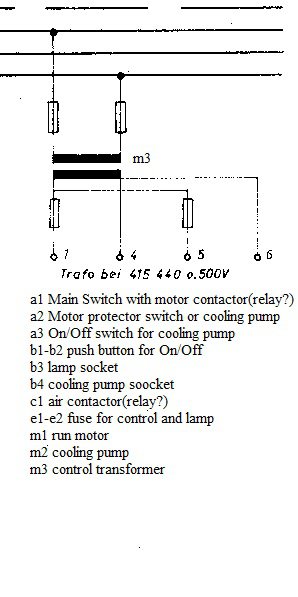

In terms of building the electrics from scratch, what I hope to do is to recreate all the functions if not the precise devices. I'll wait until I have the machine here, but I think I've found viable replacements for all the switches on the front panel. I don't know the first thing about what a 3 phase motor will require. Starters, heater(?), contactors, relays, I don't know what I'll need or how to wire it up. All I know is that my object is to have: A cooling pump and lamp socket, powered by hitting a switch each on the front panel, a motor start switch, and a motor off switch, along with the emergency kill switch(which by the way looks very ad hoc on my machine, as if it was something added for import due to OSHA regs or maybe something added late in the model run... Not sure. Looks very ad hoc in its box on the front the way it's placed.

So basically, start by figuring on a start and stop circuit and whatever it takes to make the motor go. Accessory sockets can come later. Whether I am able to use the existing motor, or have to buy a replacement or get that one repaired, it will be 240, 15hp. Once I get the lathe here, I'll look closer at the engine shaft.

I'm more than happy to buy what I need so far as parts. I just need to figure out a list and go with it. So all you 3 phase electrical/machine electrical wizards put on your thinking caps. I've a whole electrical system to build, more or less. I'll get an appropriately-sized enclosure for mounting in roughly the same place the original must have been.

By the way, looking at the weather may have pushed up my schedule to go get the lathe and bring it home. There's nothing but rain in forecast after Friday for the following week. We're just now dry enough I could get from the driveway to the barn. My window may be Thursday-Friday this week. After that, who knows? If that happens, and I come down Thursday or Friday, maybe a good chance to chat.

Thanks!

Mark