- Joined

- Jan 6, 2013

- Messages

- 125

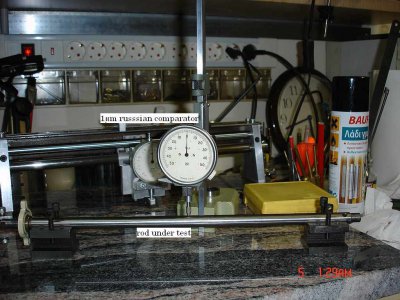

Fig 1 1µm Comparator by IZMERON

The method for verifying the epipedometro using the facilities available,

including instruments and knowledge, is as follows.

Using a 1μm resolution dial comparator,mounted on a height gauge by an adapter i made

Fig 2 Dial ind on height comparator

I measured the sagitta (bending) at the center and at intervals of 2cm along the length of the rod.This

is another rod for the demonstration.

Fig 3 Measuring the straightness

Fig 3 Measuring the straightnessThe rod is supported on V blocks.The measurement was taken by rotating carefully the rod and noting the max deviation.

First measurements showed a sagitta of 4μm that is a deviation of 2μm from straightness. It may seem brutal,

but i bent the rod by hand pressure, mounted on the V blocks using soft pads in the V and very easily,after only 2 attempts

there was no sensible movement of the dial comparator needle,all along the length.The measurement is rather difficult.

Temp was 20o C but the slightest vibration from passing cars affects it though my cave is on concrete floor.

I will continue,if there is any interest.

Ariscats