- Joined

- Jan 24, 2015

- Messages

- 239

Dear All,

I have decided to put together a build thread for my next engine, Elmer Verburg's Grasshopper (grasshopper beam )engine. Plans are here. I decided on this engine because the mechanism of operation is interesting. This article at Wikipedia discusses how it operates.

The design is really going to push the envelope of my Sherline equipment. So, I also am using this build as an excuse to upgrade my mill to a PM 25V . Unfortunately, the mill is not here yet, so we will see how things proceed.

. Unfortunately, the mill is not here yet, so we will see how things proceed.

I posted a little bit ago the making of the flywheel. That post is here.

The next bit I made, because I had the metal on hand, was the crankshaft.

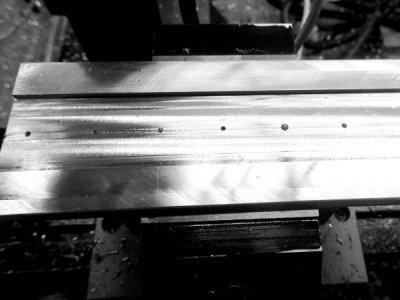

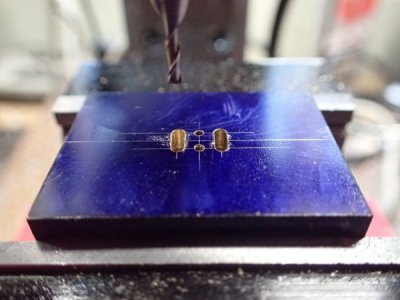

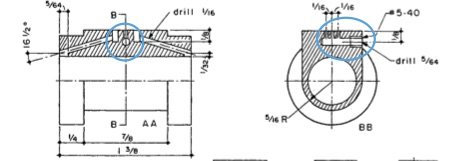

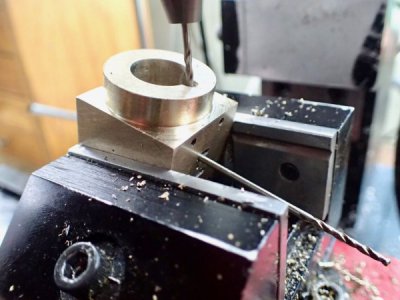

First I turned a 1"-ish long bit of 1" round 12L14 to clean up it up and bring it to nominal size and drilled and reamed the 3/16" center hole for the shaft (operation not shown). I then transferred the chuck to my Sherline mill and centered the piece under the spindle with my CoAx. I then drilled and tapped the offset for the connecting rod (5-40). Then the counter-weight profile was cut.

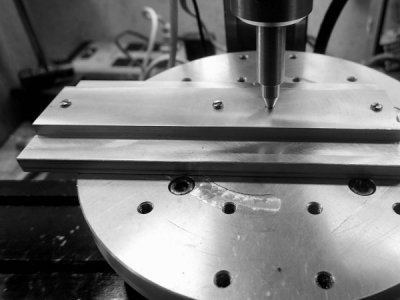

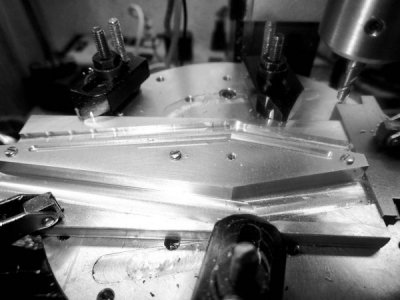

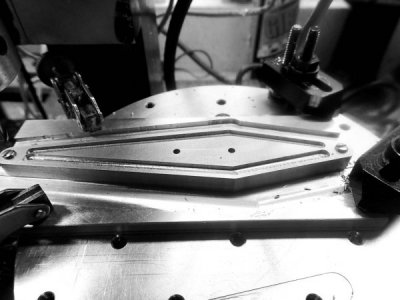

Cutting the counter-weight profile using a 3/8" 2 flute endmill.

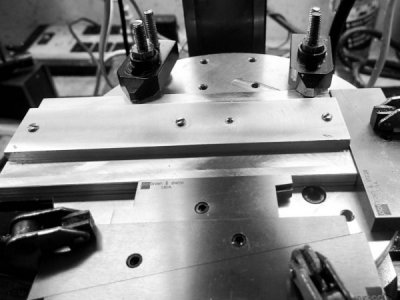

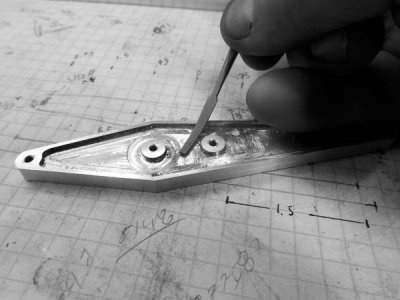

Finished counter-weight profile. I followed up with some light chamfering.

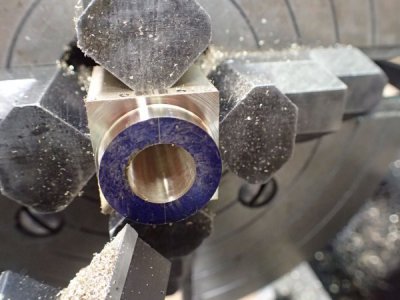

I then returned the chuck to the mill and carefully parted off the piece, leaving the width 10 thou oversized. I always seem to get a bit of scalloping when parting. The extra material was removed by draw filing to the final width, with some light hand chamfering of the edges.

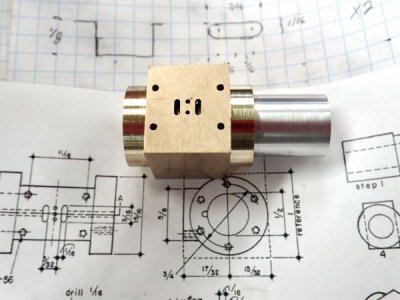

The shaft portion of the crank is 1/4" drill rod (W2) cut to proper length. I turned the mounting shoulder to a shrink fit. Then I chilled the shaft in my freezer, and gently heated the journal with a propane torch. I then put the journal and the shaft together with just a touch of green loctite. After returning to room temperature, the pieces are quite solidly joined.

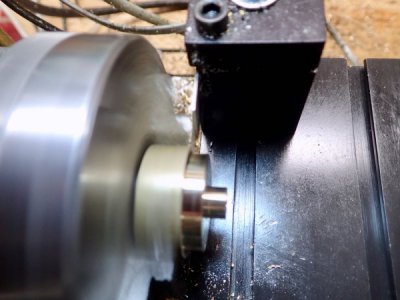

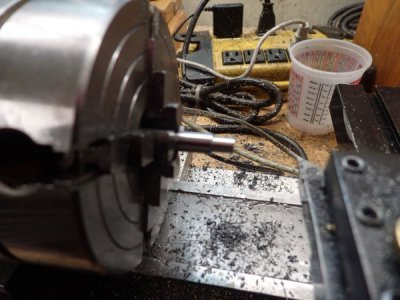

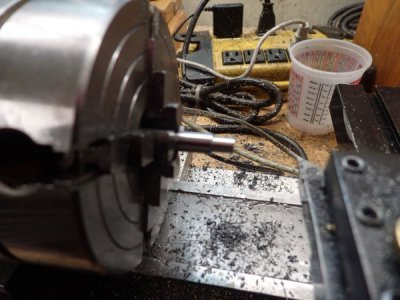

Turning the shoulder on the shaft, or a nice picture of my power strip.

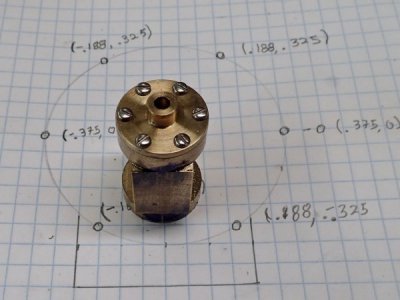

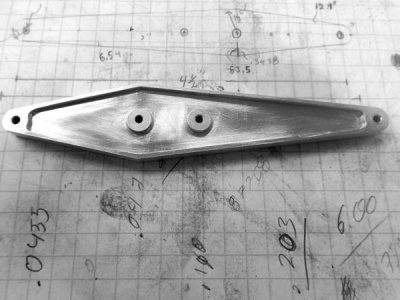

The finished crankshaft. I may try to smooth it a bit more.

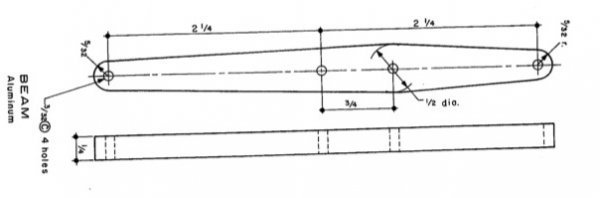

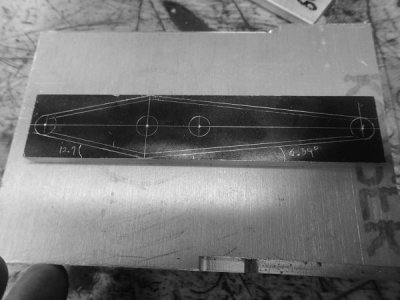

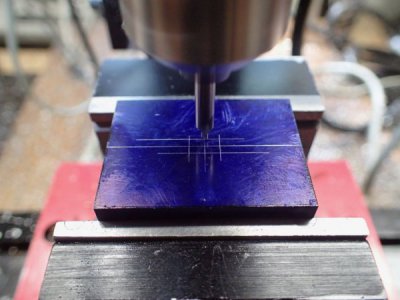

Next up is the beam. This is a bit tricky, since the pivot point is off-center. Also, the location various attachment points is critical, so careful measurements must be done.

Until then, thanks for watching!

Tom

I have decided to put together a build thread for my next engine, Elmer Verburg's Grasshopper (grasshopper beam )engine. Plans are here. I decided on this engine because the mechanism of operation is interesting. This article at Wikipedia discusses how it operates.

The design is really going to push the envelope of my Sherline equipment. So, I also am using this build as an excuse to upgrade my mill to a PM 25V

. Unfortunately, the mill is not here yet, so we will see how things proceed.

. Unfortunately, the mill is not here yet, so we will see how things proceed.I posted a little bit ago the making of the flywheel. That post is here.

The next bit I made, because I had the metal on hand, was the crankshaft.

First I turned a 1"-ish long bit of 1" round 12L14 to clean up it up and bring it to nominal size and drilled and reamed the 3/16" center hole for the shaft (operation not shown). I then transferred the chuck to my Sherline mill and centered the piece under the spindle with my CoAx. I then drilled and tapped the offset for the connecting rod (5-40). Then the counter-weight profile was cut.

Cutting the counter-weight profile using a 3/8" 2 flute endmill.

Finished counter-weight profile. I followed up with some light chamfering.

I then returned the chuck to the mill and carefully parted off the piece, leaving the width 10 thou oversized. I always seem to get a bit of scalloping when parting. The extra material was removed by draw filing to the final width, with some light hand chamfering of the edges.

The shaft portion of the crank is 1/4" drill rod (W2) cut to proper length. I turned the mounting shoulder to a shrink fit. Then I chilled the shaft in my freezer, and gently heated the journal with a propane torch. I then put the journal and the shaft together with just a touch of green loctite. After returning to room temperature, the pieces are quite solidly joined.

Turning the shoulder on the shaft, or a nice picture of my power strip.

The finished crankshaft. I may try to smooth it a bit more.

Next up is the beam. This is a bit tricky, since the pivot point is off-center. Also, the location various attachment points is critical, so careful measurements must be done.

Until then, thanks for watching!

Tom

.

.