- Joined

- Dec 9, 2017

- Messages

- 11

After looking at lots of used lathes online, I came across a one-owner 2001 G4016 just 8 miles away. Super-low hours; there appears to be far more dust than rust or wear. $2600 was more than I wanted to pay, but there's no shipping or sales tax, plus I can have it now...

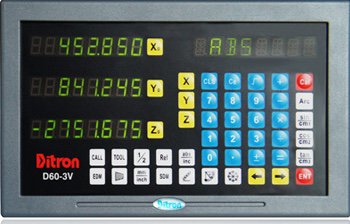

I have a number of light projects of my own, but plan to offer local lathe services as a hobby/money-maker (I'm retired). DRO and a good QCTP setup are at the top of the list once I get through cleaning the machine and checking the setup. What worthwhile improvements/upgrades have other owners installed?

I have a number of light projects of my own, but plan to offer local lathe services as a hobby/money-maker (I'm retired). DRO and a good QCTP setup are at the top of the list once I get through cleaning the machine and checking the setup. What worthwhile improvements/upgrades have other owners installed?