-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Had a thought: is there a small version of a co-ax indicator for small mills?

- Thread starter RaisedByWolves

- Start date

- Joined

- Apr 23, 2018

- Messages

- 6,608

You can, but it changes the accuracy somewhat.

How much I don't know, but I made a 6" probe that is "Perfect" in concentricity, shape and rigidity, but the result was less than spectacular.

I have it, Im proud of it, its "pretty" (Grey case coloring), but a sundial is nearly as accurate for Tool&Die work as the Blake is with this thing installed.

Ill post a pic tomorrow if I think of it.

The Blake is a comparator. Sure, the probes are sized, but think about it- there are very very few points (mathematical limits, like sin pi/2 = 0) where the gauge works as a 1:1 gauge. It is sensitive and accurate, so it is a comparator, not a measuring tool. You're centering, there's no dimension to measure. Just relative deflection.

Last edited:

You really don't need a special attachment to use a DTI for locating a hole. The stem on the DTI, typically 3/16 in, can be chucked up in the spindle directly and then you just turn the spindle by hand.

Sent from my Pixel 7 Pro using Tapatalk

Sent from my Pixel 7 Pro using Tapatalk

- Joined

- Sep 10, 2022

- Messages

- 944

SPI makes / made a version of what you're describing. And Gem made a two-face DTI to eliminate the need for a mirror.

GsTView attachment 453711

I have used that same one for years. I love it!

Cutting oil is my blood.

- Joined

- May 7, 2023

- Messages

- 1,485

Right, it’s just that it takes .0003 and turns it into .0016 with something this long.The Blake is a comparator. Sure, the probes are sized, but think about it- there are very very few points (mathematical limits, like sin 0 = 1) where the gauge works as a 1:1 gauge. It is sensitive and accurate, so it is a comparator, not a measuring tool. You're centering, there's no dimension to measure. Just relative deflection.

Here’s the culprit. Been sleeping in the bottom of the box for decades so the got a bit rusty looking.

And down in the basement where it lives.

On top is the rod that goes in the holder on the B-port, then the fiber rod that comes with the kit, then the long probe.

Pic are sideways but you get the idea.

The real problem I had with the exponential on these was due to the cylinder I was trying to pick the center of was out of round.

For a truly round or roundish cylinder it’s not as big a deal, but an egg shaped cylinder made my head spin.

- Joined

- Jan 4, 2021

- Messages

- 1,894

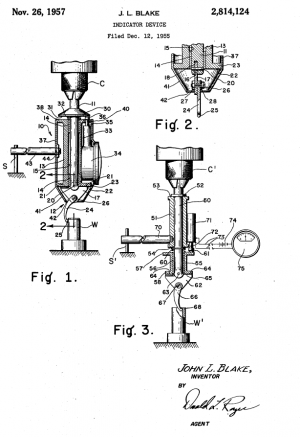

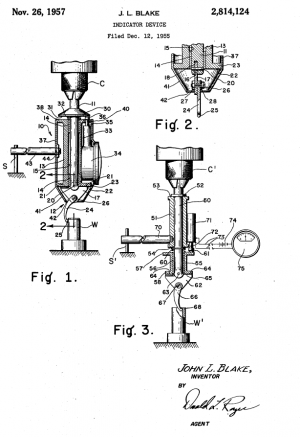

All of the Coaxial Indicators are knock-offs of the original Blake design

Here are a few alternatives that work with "vertically challenged" mills, including a link to one of Stefan's videos where he shows how you can mount a DTI so the face is always visible.

A vertical DTI (dial on the back) mounted in a jig-border style holder also works well:

Here are a few alternatives that work with "vertically challenged" mills, including a link to one of Stefan's videos where he shows how you can mount a DTI so the face is always visible.

A vertical DTI (dial on the back) mounted in a jig-border style holder also works well:

- Joined

- Feb 1, 2015

- Messages

- 9,646

I have typically used my edge finder to locate the center of a round feature and it is accurate to +/-.0001" However, it is also more time consuming as I have to locate four edges on the four quadrants.

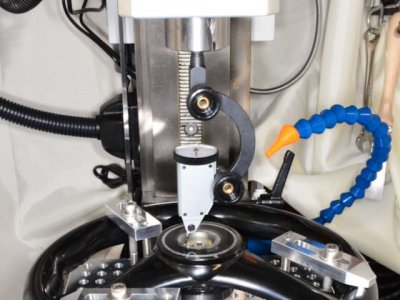

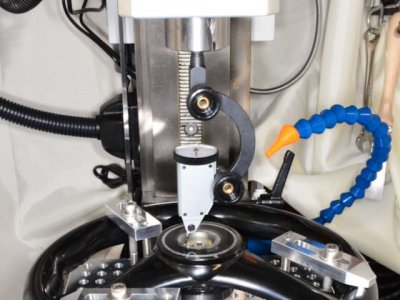

I purchased a miniature magnetic test indicator holder some time ago and it has been my go-to method of checking runout, tramming a face, etc. The magnetic base will mount to the spindle but it isn't very stable. This morning, I made an adapter for the holder that will fit in the 3/4" collets that I use for my TTS tooling system which will mount the indicator directly in the spindle. It requires only about 3" of quill clearance and can indicate holes from .1" to 16" in diameter or bosses essentially to zero diameter.

To make the adapter, I drilled and tapped a hole for the M5 thread in a short length of 3/4" rod. That was it. The indicator holders can be found at a very reasonable cost. In fact, I ordered one on Amazon for less than $10 this morning. Aside from the adapter, the only thing missing is the test indicator itself. Most of us have one or more in the shop and it can easily be moved for this when needed or a dedicated test indicator can be purchase for reasonable cost.

Here, it is mounted in the Tormach spindle. Centering agrees with edge finder centering to .0001"

The link to the holder on Amazon.

I purchased a miniature magnetic test indicator holder some time ago and it has been my go-to method of checking runout, tramming a face, etc. The magnetic base will mount to the spindle but it isn't very stable. This morning, I made an adapter for the holder that will fit in the 3/4" collets that I use for my TTS tooling system which will mount the indicator directly in the spindle. It requires only about 3" of quill clearance and can indicate holes from .1" to 16" in diameter or bosses essentially to zero diameter.

To make the adapter, I drilled and tapped a hole for the M5 thread in a short length of 3/4" rod. That was it. The indicator holders can be found at a very reasonable cost. In fact, I ordered one on Amazon for less than $10 this morning. Aside from the adapter, the only thing missing is the test indicator itself. Most of us have one or more in the shop and it can easily be moved for this when needed or a dedicated test indicator can be purchase for reasonable cost.

Here, it is mounted in the Tormach spindle. Centering agrees with edge finder centering to .0001"

The link to the holder on Amazon.

- Joined

- Jul 28, 2017

- Messages

- 2,399

The issue I see with that jig borer scheme is that the horizontal range is directly tied to the Z axis range. It's an elegant approach but less useful for those of us who are already dealing with limits on Z.

Edit: My off-the-cuff comment is incorrect, I failed to include the adjustment range of the DTI-holder end of the jig.

Edit: My off-the-cuff comment is incorrect, I failed to include the adjustment range of the DTI-holder end of the jig.

Last edited:

- Joined

- May 7, 2023

- Messages

- 1,485

OK, I have my design worked out in my head, but Im struggling to find a suitably small indicator.

The STARRETT 80-134J fits the bill, but people want an arm and two legs for them.

Anyone know of a similar type indicator?

What Im really looking for is a drop type with a small 1"ish face. Quality doesn't matter at this point as this is strictly experimental.

The STARRETT 80-134J fits the bill, but people want an arm and two legs for them.

Anyone know of a similar type indicator?

What Im really looking for is a drop type with a small 1"ish face. Quality doesn't matter at this point as this is strictly experimental.

- Joined

- Jan 4, 2021

- Messages

- 1,894

Most companies that make/sell indicators have AGD 1 versions that have 0.0005" resolution and around a 0.125" range; here's one from SHARS:

Depending on you design, you may want to consider a back-plunger version; here's a new Starrett 196 for (probably) less than $30:

Depending on you design, you may want to consider a back-plunger version; here's a new Starrett 196 for (probably) less than $30: