- Joined

- Jun 23, 2016

- Messages

- 30

I knew this day would come...and I've been dreading it for years...but it's here....and approaching quickly.....MOVING DAY.

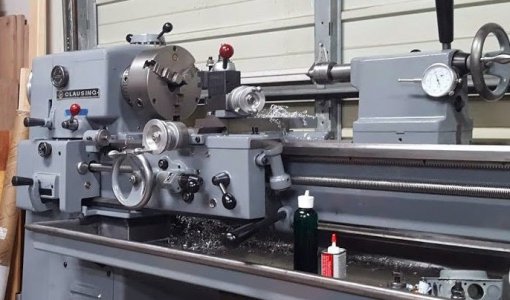

I've managed to squeeze a lot of tool into a 440 sq ft space but right now my heaviest and move difficult to move is my Clausing 5914 12x36 lathe. For my other tools I've rented a 24' Liftgate box truck and will load and move everything with that. For the lathe I've decided to move it on a trailer.

My question for you guys is do you think the Harbor Freight 1720# capacity 4x8 trailer is up to the task? I'm considering renting a 4x8 ultiity trailer from U-Haul but trailer seems like something pretty useful to have.

Just curious to hear your guys' thoughts on it. I have some friends that think it's crazy and others that don't see why it would be a problem. Thanks for any advice!

I've managed to squeeze a lot of tool into a 440 sq ft space but right now my heaviest and move difficult to move is my Clausing 5914 12x36 lathe. For my other tools I've rented a 24' Liftgate box truck and will load and move everything with that. For the lathe I've decided to move it on a trailer.

My question for you guys is do you think the Harbor Freight 1720# capacity 4x8 trailer is up to the task? I'm considering renting a 4x8 ultiity trailer from U-Haul but trailer seems like something pretty useful to have.

Just curious to hear your guys' thoughts on it. I have some friends that think it's crazy and others that don't see why it would be a problem. Thanks for any advice!