-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Harbor Freight Arbor Press Upgrades

- Thread starter minsk

- Start date

- Joined

- Feb 9, 2017

- Messages

- 5,249

I thought I wanted a ratchet on my press until I started paying attention to how I used It. I was doing more metal forming and stamping so the ratchet would work against me. For straight through work like broaching it’s great though. I now have a screw press that can do a c broach all at one time so the Whoopee mod is what works the best for my arbor press as it’s easy to set the lever arm right where I need it.Thanks; now I need to decide which mod to make (and see if I kept any of the extra ratchet wrenches when I was clearing out a couple of years ago).

- Joined

- Jun 15, 2017

- Messages

- 525

Well, Mr. Whoopee has the advantage of the 3DBB.

- Joined

- Jan 20, 2018

- Messages

- 5,631

I can't use it much anymore, it uses too much power.Well, Mr. Whoopee has the advantage of the 3DBB.

I can't take credit for the mod, though it certainly fits my style of stupidly simple designs. I found it over on HSM and was struck by its simple and obvious nature.

I copied this idea from someone else, but I modified my 2T press with a ridgid pipe threading head and added a handwheel.

I've been really pleased with how this works. Easy direction change plus a neutral position on the head. Handwheel is nice for quick positioning, then engage the ratchet. Basically the poor man's version of a real ratcheting arbor press. On occasion I've swapped to a longer piece of pipe for a just bit more power.

I've been really pleased with how this works. Easy direction change plus a neutral position on the head. Handwheel is nice for quick positioning, then engage the ratchet. Basically the poor man's version of a real ratcheting arbor press. On occasion I've swapped to a longer piece of pipe for a just bit more power.

- Joined

- Feb 9, 2017

- Messages

- 5,249

This is the ratchet mod I saw and was shooting for. Even found a ridged pipe threading head. Much better than than a socket ratchet IMHO.I copied this idea from someone else, but I modified my 2T press with a ridgid pipe threading head and added a handwheel.

I've been really pleased with how this works. Easy direction change plus a neutral position on the head. Handwheel is nice for quick positioning, then engage the ratchet. Basically the poor man's version of a real ratcheting arbor press. On occasion I've swapped to a longer piece of pipe for a just bit more power.

- Joined

- Jan 4, 2021

- Messages

- 1,796

OK, it's been almost a year, but I finally got around to adding ratcheting capability to my 1T HF and 1/2T Micromark Arbor Presses. As noted above, I had previously made the tooth removal mod to both, but wanted to go further. I considered the sliding pinion, but that still wasn't the best option IMHO, so I started thinking about using a ratchet wrench. I didn't want to go to the effort of adding a square hole to the end of the pinion like this; and even though I hadn't seen this post, I came up with a similar idea: mill a hex on the end of the pinion shaft to accept a standard size socket, then just use said socket with a regular ratchet wrench. While the pinion shaft was out of the frame, I drilled & tapped a hole in the opposite end so I could add a hand wheel to make raising the ram faster.

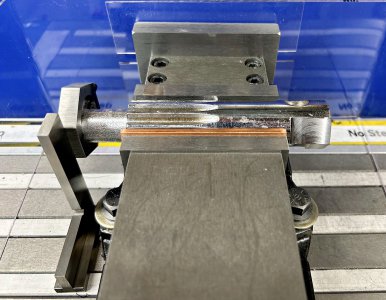

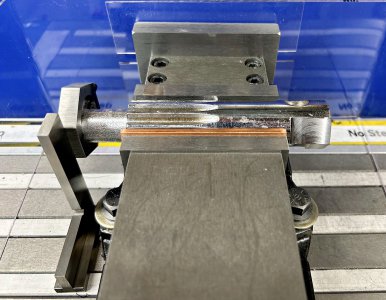

Holding the pinion from the 1/2T Press in the mill vise with the aid of a copper bar, and @Doug Gray 's Indexing Plates made the job of milling the 15/16" hex fairly straight forward:

Then to the lathe to drill & tap the other end, using the shaft center to make alignment of the Steady Rest easy:

After everything was back together, it looks pretty good:

Yes, the ratchet is further from the end of the pinion shaft than if I had placed a square hole in the shaft, but only by about 3/8". The gizmo attached to the top of the ram is an accessory from Micromark that provides a depth stop.

I'll post the finished 1T HF Press once a few items arrive this weekend (machining operations were the same, but the hex is 30mm).

Holding the pinion from the 1/2T Press in the mill vise with the aid of a copper bar, and @Doug Gray 's Indexing Plates made the job of milling the 15/16" hex fairly straight forward:

Then to the lathe to drill & tap the other end, using the shaft center to make alignment of the Steady Rest easy:

After everything was back together, it looks pretty good:

Yes, the ratchet is further from the end of the pinion shaft than if I had placed a square hole in the shaft, but only by about 3/8". The gizmo attached to the top of the ram is an accessory from Micromark that provides a depth stop.

I'll post the finished 1T HF Press once a few items arrive this weekend (machining operations were the same, but the hex is 30mm).

- Joined

- Jan 4, 2021

- Messages

- 1,796

Thanks, Doug. When I was planning the work I knew that while I could use a Hex collet block, but I'd also need to use a "Foot Stock:" I have one, but setting it up would have been unnecessary extra work. The Indexing Plates made it easy.

- Joined

- Jan 4, 2021

- Messages

- 1,796

1 Ton HF Press Completed:

In addition to machining the right end of the pinion shaft to a 30mm hex and adding the hand wheel on the left end, I inserted 22mm x 0.2mm shim washers at the inside & outside bearing faces on the left end of the shaft (a little dab of grease helped position the inside one since the OD of the shim was larger than the minor diameter of the pinion splines and the shim needed to be placed before inserting the shaft). The shims significantly improved the shaft rotation. I also had to face 0.5mm off of one face of the shaft collar (which also helped with the smoother rotation).

I have shims coming (due in the end of next week) for the 1/2T Press, but it was better to begin with. I will probably also clean up the inside face of the shaft collar on that one, too.

In addition to machining the right end of the pinion shaft to a 30mm hex and adding the hand wheel on the left end, I inserted 22mm x 0.2mm shim washers at the inside & outside bearing faces on the left end of the shaft (a little dab of grease helped position the inside one since the OD of the shim was larger than the minor diameter of the pinion splines and the shim needed to be placed before inserting the shaft). The shims significantly improved the shaft rotation. I also had to face 0.5mm off of one face of the shaft collar (which also helped with the smoother rotation).

I have shims coming (due in the end of next week) for the 1/2T Press, but it was better to begin with. I will probably also clean up the inside face of the shaft collar on that one, too.

Last edited: